How can the pipe induction heat treatment furnace be efficiently produced?

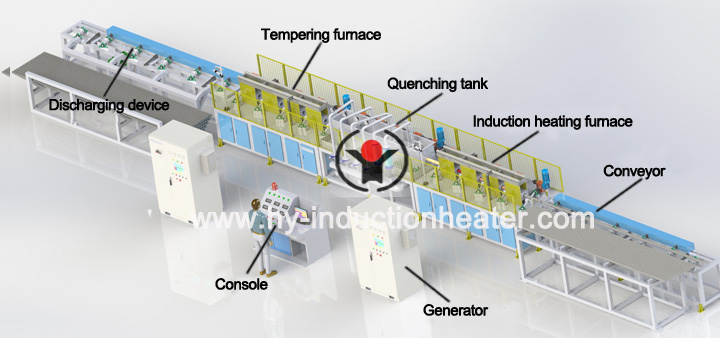

Induction heating equipment is used in the production and processing of pipe induction heat treatment furnace, which has a high heating efficiency for all kinds of pipelines, whether seamless steel pipe, thick-walled steel pipe, oil casing, stainless steel pipe and other materials can be applied to induction heating equipment hot processing. For the majority of users, how to buy high-quality and low-cost pipe induction heat treatment furnace, how to achieve high-yield and high-efficiency production is a crucial issue. According to Forever years of production experience, the following is to improve the efficiency of pipe induction heat treatment furnace.

1. Structural design improvement

The pipe induction heat treatment furnace produced by Forever adopts the structure design of mechatronics, which makes the corresponding speed of the whole induction heating equipment faster and more stable. At the same time, it also enhances the heating efficiency of induction coil for workpiece, effectively improves the quality of pipe after hardening and tempering process and meets the production needs of users. Forever will vigorously promote the development of induction heating equipment.

2. The adjustment for heating the pipes

The adjustment of pipe heating is an external cause. The inductor of the heating equipment is customized according to the size of the workpiece of the user to reduce the loss of heat and improve the heating efficiency. In addition, the feeding speed of the transportation system is regulated reasonably so as to achieve the perfect match between heating and feeding, which ensures the efficient heating of the pipe and at the same time enables the pipe to be heated. Heating quality meets user requirements.

3. Pay attention to safe operation.

According to the normal operation rules, it can not only realize the high yield and high efficiency of pipe induction heat treatment furnace, but also is a kind of safety guarantee. So in operation, before starting, check the pipe anticorrosive heating equipment circuit, check whether the connection is normal, in order to prevent danger; pipe induction heat treatment furnace heating need not be started for preheating in advance, equipment start-up success rate is high; heating process. If abnormal phenomena are found, stop checking, troubleshooting after production. Pipe induction heat treatment furnace has automatic alarm device. If it rings, you should immediately stop production and repair according to instructions.

Welcome to contact with us for more details and videos about pipe hardening and tempering furnace.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment is glad to be your partner in the field of induction heating.

Post time: 09-15-2018