High quality pipe induction heat treatment furnace is sold all over the world !

Founded in 1999, Forever company has ranked the top three in the heat treatment industry. The new generation of stainless steel pipe induction heat treatment furnace automatic intelligent represents that Forever has broken a new record. We will continue to provide the best selection for the users of stainless steel pipe induction heat treatment furnace. We will continue to develop and update and design for pipe induction heating equipment. Together with our customers, we will “create a new era of automation and intelligence”. Forever pipe induction heat treatment furnace is sold all over the world.

Forever induction heating furnace such as stainless Steel Tube Heating Equipment, Stainless Steel Tube Expanding Heating Furnace, Stainless Steel Tube Tempering and Tempering Production Line, Stainless Steel Tube Annealing Furnace, Axle Heat Treatment Heating Equipment, Axle Heat Heating Equipment, Single Pillar Heat Treatment Equipment, Spring Plate Heat Treatment Heating Equipment, Cutter Angle Plate Forging Heating Furnace, Foundation Bolt Heat Treatment Production Line, wire, square tube heat treatment production line, billet continuous casting and rolling production line, wind power anchor bolt heat treatment furnace, pipe shrinkage heating production line, rail surface quenching production line, billet heating equipment have been exported to Indonesia, Ethiopia, the United States, Russia, Taiwan, Shanghai and Vietnam and so on.

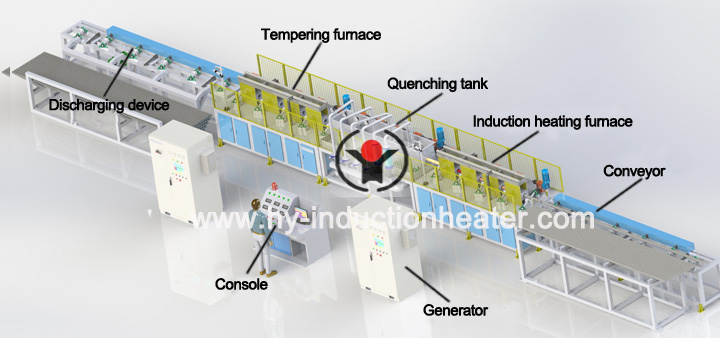

Stainless steel tube pipe induction heat treatment furnace refers to the equipment heating treatment of stainless steel pipes, its configuration includes medium frequency induction heating system, energy-saving air-cooled induction heating power supply, PLC fully automatic operation console, input device, output device, closed cooling tower, etc., other optional equipment can be matched.

Working characteristics of stainless steel pipe induction heat treatment furnace

The main production control process of stainless pipe induction heat treatment furnace mainly control the heating temperature, stainless pipe running speed, rotating speed and frequency. The regulation methods of specific projects are as follows.

The movement speed of the regulating mechanism of the feeding and unloading mechanism is controlled by the central console and the action of the hydraulic cylinder is controlled by regulating the flow of the valve, so that the feeding and unloading mechanism can be synchronized and coordinated.

The advance speed and rotation speed of stainless steel pipe are regulated by adjusting the installation angle of rollers and the rotating speed of motors. The advance speed and rotation speed of stainless steel pipe are regulated and the technological requirements are realized. The forward speed of stainless steel pipe can be adjusted in a wide range and the adjustment range of rotation speed can be controlled.

The heating temperature regulation of stainless steel pipe induction heating equipment is controlled by the famous brand RT thermometer. Then, the temperature information is transmitted to the central control system for processing and the processing results are fed back to the heating system to realize the closed-loop automatic control of heating temperature and heating power.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment is glad to be your partner in the field of induction heating.

Post time: 08-20-2018