Have you seen such an continuous casting billet heating furnace?

Continuous casting billet heating furnace, as one of the strong products of Forever company, has formed a deep market influence after years of accumulation. In the face of market change, Forever continue to design and develop new type continuous casting billet heating furnace, introducing medium frequency continuous casting billet heating furnace to meet the user’s product requirements and create customized products according to the characteristics of the user. We will introduce the advantages of continuous casting billet heating furnace.

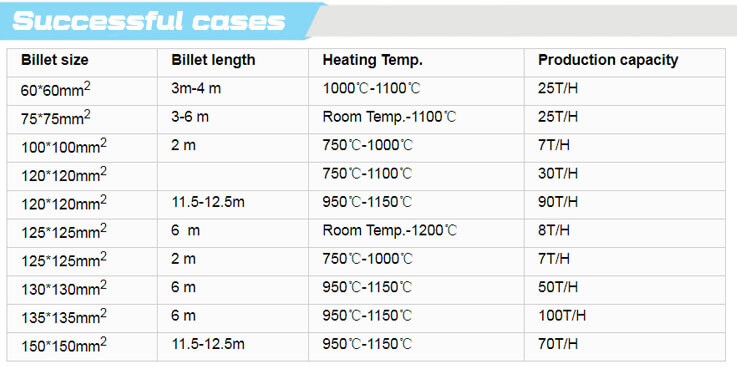

As one of the main products of continuous casting billet heating furnace market, induction billet heater is the main field contested by many manufacturers, and the market competition is extremely fierce. In order to meet the needs of customers,Forever make customized product after considering user’s operation status and environment. The products are well received by the market after the introduction of the continuous casting billet heating furnace.

The market share of medium frequency heating equipment has been steadily increasing.

Exclusive configuration of continuous casting billet heating furnace

1. According to the quantity of power supply, four induction billet heater (two work and two reserve) are selected, which is supplied power by onet set of converter.

2. Between the induction heating coils, we will set up three roller table for conveying and the roller distance is 2.6m. Two sets of pinch rollers are required to be set in the direction of ingot. The distance between rollers is 1.6 meters and the diameter of rollers is 200 mm. The length of the effective inductor is about 1 meters, and the total length of the inductor is 1.2 meters.

3.The inner space of the continuous casting billet heating furnace: the billet is 150×150 square billet, the inside of the inductor is also a square square hole, the size is 280X280, the thickness of the refractory is 20mm, and the net space of the billet and the refractories is 45mm.

Reliability advantage of continuous casting billet heating furnace

1. The temperature of the billet is controlled by the infrared temperature measuring system of the medium frequency heating furnace. According to the time prediction and material condition, the furnace temperature is set reasonably, so that the steel billet can meet the requirements of the user in a certain time.

2. Cascade control system is a system in which two regulators work in series, and the output of one regulator acts as a given value of the other one. This system improves the dynamic characteristics of the continuous casting billet heating furnace process, improves the control quality of the system, which can quickly overcome the two disturbances entering the secondary circuit, improves the working frequency of the system and has the influence on the change of the load.

3. The continuous casting billet heating furnace can meet the requirements of various environmental protection departments. The intermediate frequency heating equipment is fast heating, and the surface oxide layer of the heating material is very few. It is easy to realize automatic control and save effort. The most energy-efficient heating method in induction heating equipment is heated from room temperature to 1100 °C.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of long bar heat treatment machine is glad to be your partner in the field of induction heating.

Post time: 08-01-2018