Advantages of medium frequency heat treatment and tempering equipment

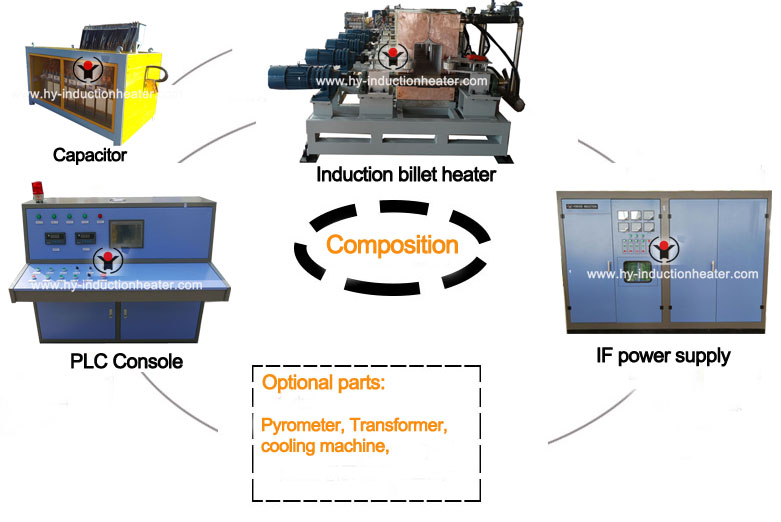

The metal quenching and tempering equipment consists of three parts: medium frequency induction heating power supply, quenching equipment (including inductor) and tempering equipment. This induction heating production line has a series of advantages, such as good quality, fast speed, less oxidation, low cost, good working conditions and easy to complete mechanization and initiative.

5 advantages of medium frequency heat treatment and tempering equipment:

1. Active feeding system: workers put the steel bar on the shelf, and then the active feeding system will transfer the workpiece to the running roller table.

2. Induction hardening: the transmission system runs at a stable speed, and the transmission system will transport the workpiece in the induction heater. The infrared thermometer will actively monitor and control the temperature of the workpiece, and actively measure the temperature in the process of temperature measurement. After the steel bar temperature reaches the quenching temperature, it is cooled in the cooling equipment. The drive system then feeds the bars into the feed system, waiting for the next heat treatment.

3. Tempering system of quenching and tempering heat treatment equipment: the workpiece after quenching will be transferred to induction heater for reheating under the control of infrared thermometer. The workpiece is then moved to the induction heater to store the heat. After holding the temperature time, the workpiece will be sent to the parallel roller table.

4. Active discharge system: the workpiece will be transported to the discharge system for natural cooling.

5. Steel bar induction heat treatment furnace has the function of checking and storing.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 04-20-2020