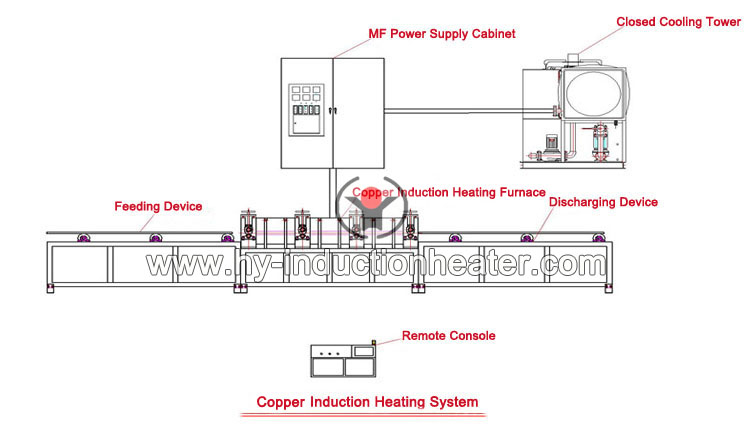

Fabrication supply & commissioning of induction heating system

The induction heating system efficiency for a specific application is effected by several factors:the power supply design, the characteristics of the component itself, the design of the inductor.Forever induction heating system has self-designed MF and HF power supply and mature induction heating technology.Forever will be responsible for fabrication supply & commissioning of induction heating system for your work piece to meet your production requirements.

Induction heating is a process which is used to bond, harden or soften steel or other metals. For many modern fabrication processes, induction heating offers an attractive combination of speed, consistency and control.

Power Supply

The size of the induction heating power supply required for heating a specific part can be easily calculated. First, one must determine how much energy needs to be transferred to the work-piece.

This depends on the mass of the material being heated, the specific heat of the material, and the rise in temperature required. Heat losses from conduction, convection and radiation should also be considered.

Forever power supply is designed and made by ourselves, which has formed closed loop with infrared thermometer device so that it can adjust and control heating temperature.

Inductor Design

It is within the inductor that the varying magnetic field required for induction heating is developed through the flow of alternating current. So inductor design is one of the most important aspects of the induction heating equipment.

A well-designed inductor provides the proper heating pattern for your work piece and maximizes the efficiency of the induction heating power supply, while still allowing easy insertion and removal of the part.

Our inductor is quick change type, which is very easily to replace.

This article is from Forever-steel ball production line manufacturer.

Post time: 09-14-2016