Detailed process of grinding rod hardening and tempering furnace

Grinding rod hardening and tempering furnace generally includes three processes including heating, quenching, tempering. Some manufacturers of grinding rod hardening and tempering furnace can only achieve heating and cooling two processes. These heat treatment processes are interconnected and continuous and can not be interrupted. Induction heating of grinding rod is one of the important processes of quenching and tempering heat treatment. There are many heating methods for metal heat treatment. Earlier, charcoal and coal are used as heat sources and gas fuels are used. The use of electricity makes heating easier to control and no environmental pollution.

The metal quenching and tempering heat treatment technology can be divided into three main categories: bar through heat treatment, bar surface heat treatment and bar chemical heat treatment. The same kind of bar can be obtained by different quenching and tempering heat treatment processes, and different internal structures can be obtained, so that different properties can be obtained. Steel bars are widely used metal parts in industry, and the microstructure of steel bars is also more complex. Therefore, there are many kinds of heat treatment processes for steel bars. When the metal workpiece is heated, the workpiece is exposed to the air, and the oxidation and decarbonization often occur (that is, the surface carbon content of parts will reduce), which has a very bad effect on the surface properties of the workpiece after the heat treatment.

The heating temperature is one of the important technological parameters of the grinding rod hardening and tempering furnace. It is the main problem to control grinding rod heat treatment quality to select and control the heating temperature of the grinding rod hardening and tempering furnace. The heating temperature varies as per different metal heat treatment methods and purpose. But generally it is heated above the phase transition temperature to obtain the internal structure of high temperature. In addition, the transformation of internal organization requires a certain amount of time, so when the bar reaches the heating temperature required by the user, it is necessary to maintain a certain time at this temperature to ensure the consistency of the internal and external temperature and make the microstructure change completely. This time is called the heat preservation time. With high energy density heating and surface heat treatment, the heating rate is very fast and there is no holding time, and the heat preservation time of chemical heat treatment is often longer.

The quenching of grinding rod hardening and tempering furnace is to heat the rods to some degrees and then put into quenching medium such as water, oil or other liquid for cooling. After quenching, the properties of the steel are hardened and brittle at the same time. In order to reduce the brittleness of steel parts, the steel bar after quenching is kept at a suitable temperature above room temperature and below 650 C for a longer period of heat preservation and cooling again.

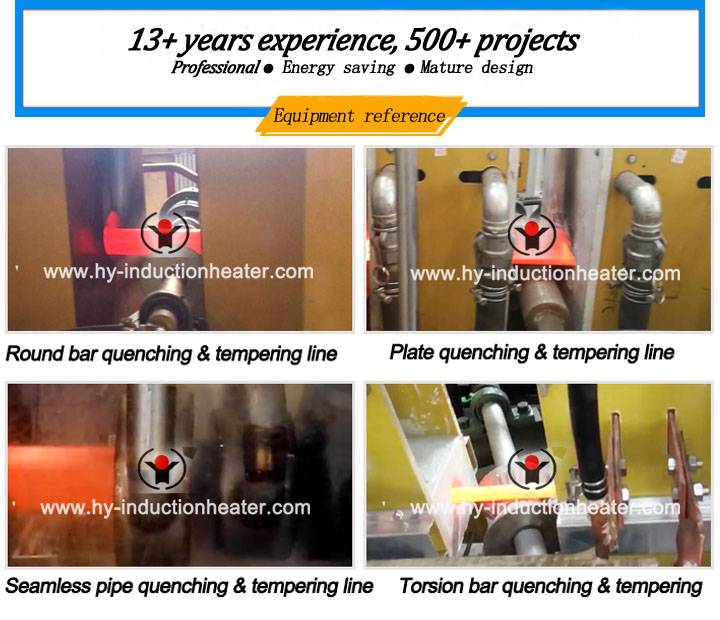

More details for bar induction heat treating furnace, welcome to contact with us.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.

Post time: 05-05-2018