Contact with Yuantuo for customized quench and temper line

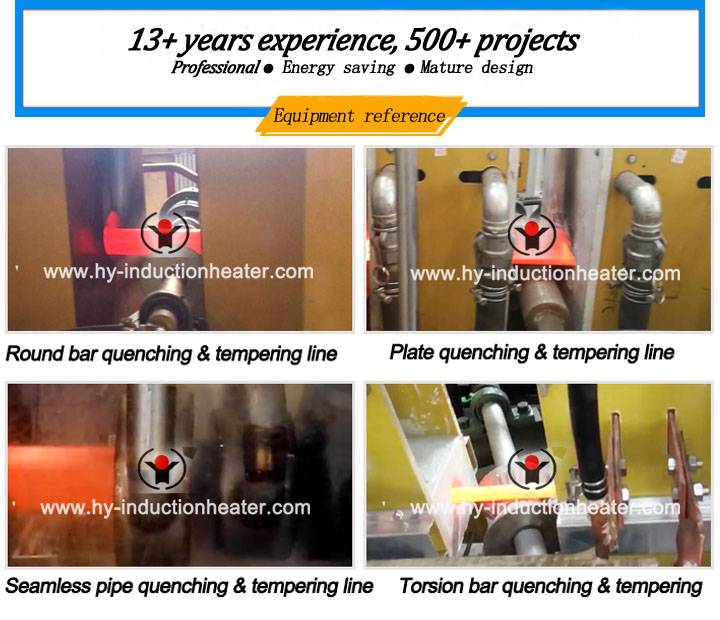

As the professional of producer of quench and temper line, Yuantuo has several orders for this project every month, especially for the sold bars. In May, 2018, we have 4 projects for quench and temper line. 3 sets of round bar quench and temper lines and 1 set of oil pipe quench and temper line.

Almost every quench and temper line from our factory is different as every customer has different requirement such as hourly capacity, bar diameter, configuration and components. Before signing the contact, our engineer will communicate with the customer to confirm what they need and then we will give the best proposal to meet customer’s requirment. So almost all the quench and temper lines are customized. After finishing the production, our engineer will go to the customer’s plant and guide installation and debuging.

The technical features of Yuantuo quench and temper lines are as follows:

1. The medium frequency quench adn temperin line has high power factor to the power grid. The voltage type series inverter power supply is used in Yuantuo medium frequency power supply. The rectification of the equipment has been operating at zero degree. It does not need the staff to adjust the rectifier and only adjust the inverter. So the medium frequency quench and temper line has high power factors, more than 0.95, and does not produce higher harmonics. Yuantuo ensure that the power factor is always above 0.95 under any working condition.

2.Medium frequency quench and temper line is more energy saving and consumption reduction. Due to the use of series resonant circuit design with small reactive current, it reduces power consumption greatly.

Compared with old common equipment, the induction heating furnace can save energy 15%-20%.

3. The production automation of the continuous quench and temper line is high. It has been able to achieve automatic unmanned automatic feeding and automatic discharging, with the special control software of the manufacturer of the electric medium frequency induction furnace, which realizes the automatic production. For different size of bars quenching and tempering, our engineer will help the operator to test the parameters and input them into PLC control system.

4. The temperature control system can realize precise control of temperature and uniform heating and on-line temperature measurement by infrared thermometer. By adjusting the working frequency of the medium frequency induction furnace, the uniform heating of the workpiece and the small temperature difference of the core table are achieved.

5. Due to the electromagnetic heating principle of the induction heating furnace, the heating of the workpiece is rapidly heating up, and the surface of the metal part produces less oxidation and decarburization. The heat efficiency is high, the heat loss is less, and the process repeatability is good.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.

Post time: 05-07-2018