Compared with conventional furnace, long bar induction heat treatment machine is much better !

In recent years, with the problem of environmental damage becoming increasingly prominent, the national requirements for environmental protection of steel heat treatment industry are becoming more and more stringent. In order to meet the current national environmental protection policy requirements, steel processing enterprises also pay more attention to the environmental protection performance of long bar induction heat treatment machine. It was a very good opportunity. So they carried out a long research on the properties of long bars again. After a long time of optimizing the design of their own equipment, we can see the environment-friendly long bar induction heat treatment machine.

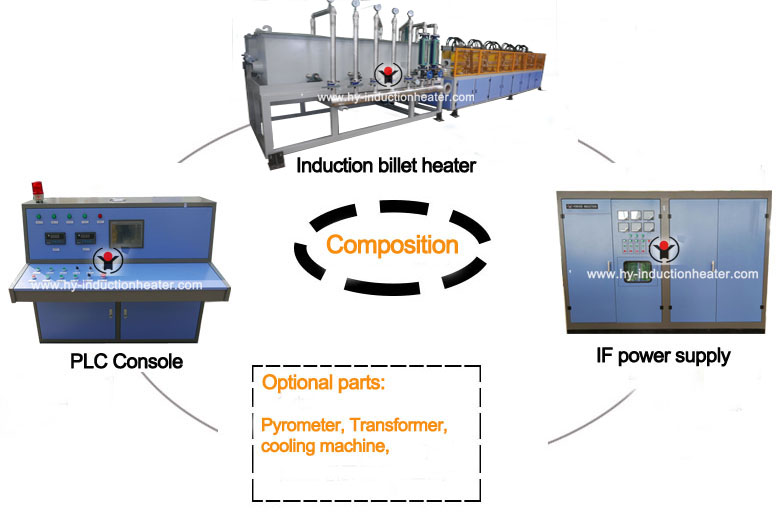

So, what are the advantages of long bar induction heat treatment machine compared with the conventional heat treatment furnace? What are the specific configuration of long bar induction heat treatment machine used by users? How about the use of the workshop working? Let’s take a look at these three problems.

What are the advantages of the long bar induction heat treatment machine compared with the traditional long bar heat treatment furnace?

1. The steel material produced by conventional bar heat treatment furnace is rough with burrs, and the output is low. Coal is used as heating energy, which causes great emission and pollution and unstable performance. The IGBT intelligent induction heating power supply of long bar induction heat treatment machine adopts parallel resonance design, phase shifting and power regulation, and the equipment is mature and stable; it has more advantages in the high power range of 3000 kW or more. DSP control, extremely fast capture and phase locked start to meet the frequent start and stop. The unique constant-power/constant-angle mode selection function of Topping Machine is available. In low-frequency band or other times when relatively large power is needed, the constant-power mode can be selected.

2. The traditional heat treatment line has high cost, high consumption and great waste of resources. The induction hardening and tempering furnace produces energy with renewable electric energy, and consumes less energy. According to different parameters of workpiece, the induction heating furnace is optimized by computer to meet the needs of workpiece with wide range of dimensions.

3. The conventional heat treatment line technology is insufficient, the quality of finished steel is not good, and the phenomenon of oxidative decarbonization is more, on the contrary, the environmental-friendly induction heat treatment furnace has changed the disadvantages of the traditional furnace, the production of steel bar material physical and chemical properties are good, no oxidative decarbonization crack deformation and other conditions, to ensure the qualified rate of finished aluminum alloy materials.

Forever is a professional manufacturer of long bar heat treatment machine with reliable performance and superior raw material. Welcome to contact us for more details.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment is glad to be your partner in the field of induction heating.

Post time: 10-20-2018