The electric heating furnace of remote development machine can be used for local heating Surface heat treatment of workpiece. This heat treatment process is often used for surface quenching, local annealing or tempering, and sometimes for integral quenching and tempering.

When the induction heating equipment is alternating current at a certain frequency, there will be alternating magnetic field around the inductor. The electromagnetic induction of alternating magnetic field acts on the metal workpiece, which causes the induction current to be produced inside the workpiece. The induced current is unevenly distributed on the surface of the metal workpiece, and the density of the induced current is very high on the surface of the workpiece and gradually decreases inward. This phenomenon is called skin phenomenon. The high density current changes from electric energy to thermal energy on the surface of the workpiece, which is the temperature rise of the surface of the workpiece, so that the heat treatment of the time surface is carried out. The higher the current frequency, the greater the current density difference between the surface and the interior of the workpiece, and the thinner the heating layer. After the heating layer temperature exceeds the critical point temperature of the steel, the surface quenching can be realized. Characteristics and applications of local surface heating in electric furnace for electric heat treatment of remote development machine:

1. The workpiece can be selectively heated, the deformation of the local heating workpiece is small, and the power consumption is small.

2, the induction heating equipment does not produce waste gas, waste smoke, noise and dust and other harmful substances to achieve green production;

3. Based on the principle of electromagnetic induction heating, the heating speed of workpiece is fast and the surface oxidation decarbonization of workpiece is light.

4, the hardened layer of workpiece surface can be adjusted according to the need of heat treatment furnace, which is easy to control.

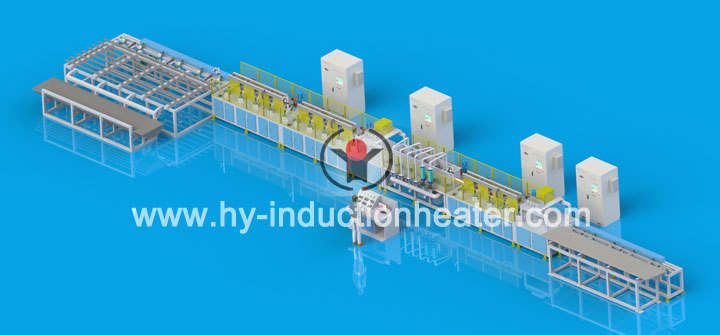

5. Heat treatment quenching furnace can be installed on machining production line, which is easy to realize mechanization and automation, convenient management, reduce labor force and improve production efficiency.

6. The microstructure, hardness, strength and toughness of the hardened layer are fine.

7, after surface quenching, the surface layer of the workpiece has large compression internal stress, and the fatigue fracture resistance of the workpiece is higher.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 05-13-2019