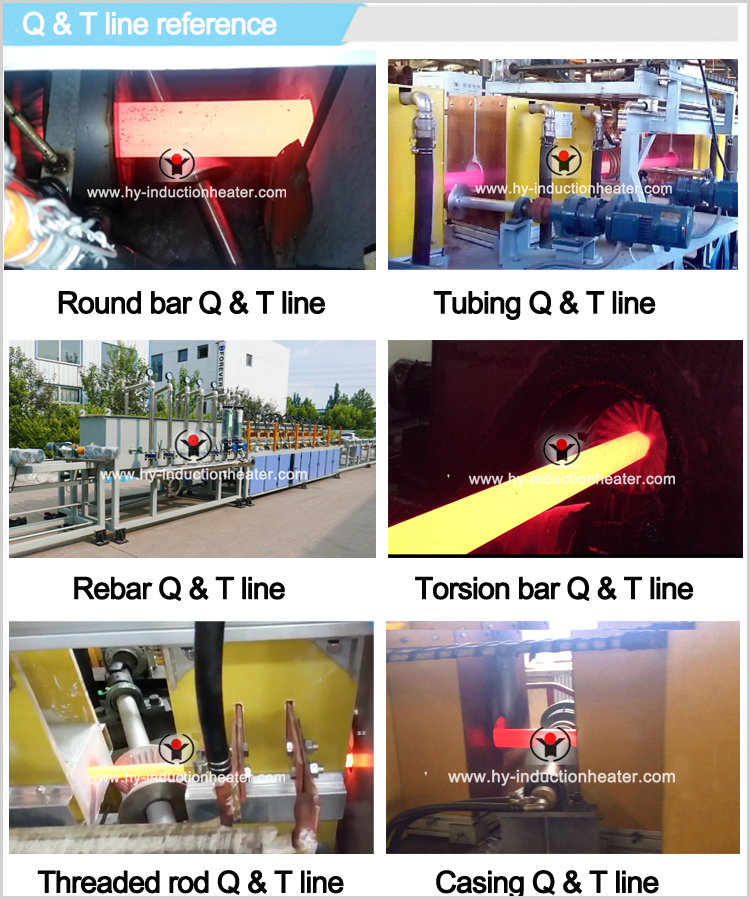

FOREVER mechanical and electrical company specializes in the production of bar induction quenching and tempering line. According to your process requirements, we can customize high-quality medium frequency induction heating furnace for you: steel bar heating furnace, steel tube heating equipment, billet heating furnace, steel tube heat treatment furnace, etc. the equipment is energy-saving, environmental protection, quality assurance, affordable and good service. I believe you can choose FOREVER.

Characteristics of induction hardening and tempering line of bar:

Characteristics of induction hardening and tempering line of bar:

1. In the transmission design of induction hardening and tempering line of bar, V-shaped roll arranged obliquely is used to reduce the run out of small diameter direction. In order to make the workpiece produce self rotation movement, the pressure jet cooling technology is adopted. The cooling medium is ejected from the pressure nozzle with a certain pressure to form a turbulent continuous water flow, and the continuous jet before the liquid flow is broken is used to impact the steel bar for cooling. Good penetration, suitable for the environment with thick water vapor film, high cooling efficiency.

2. When the cooling water contacts the hot steel bar, it will vaporize and form a vapor film. Because of the continuous water flow impinging on the surface, it is difficult to form a stable vapor film on the surface. When the surface temperature drops rapidly, nucleate boiling is the main heat transfer mode. At the beginning of nucleate boiling, the heat flux Q increases sharply. When the surface temperature of steel bar and steel tube drops below the lower limit of bubble boiling, the boiling stops and the heat flux decreases.

3. In the case of water spray quenching in production, the quenching intensity H can reach 3-4. In the case of high-speed cooling, the steel bars are all cooled below the martensitic transformation point in a few seconds.

4. The core is basically transformed into homogeneous and fine martensite, and the structure of the whole cross section of the workpiece tends to be the same, which makes the performance of the steel fully play. In the water spray cooling stage of quenching process, the cooling water is ejected from the annular water spray device and converges to the workpiece surface, with the water outlet pressure as high as 0.3MPa. The steam film on the surface of the workpiece is fully destroyed, so that the quenching efficiency and product quality are greatly improved. The matrix structure is basically transformed into martensite, and the structure is more uniform, which is conducive to the improvement of strength and toughness after tempering.

FOREVER mechanical and electrical bar induction quenching and tempering line has now been widely used in domestic and foreign markets with affordable price and reliable quality, and is widely recognized by users. If you are also interested in the metal heat treatment equipment, you are welcome to visit the factory at any time to learn or directly bring materials to the factory for free trial!

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 04-23-2020