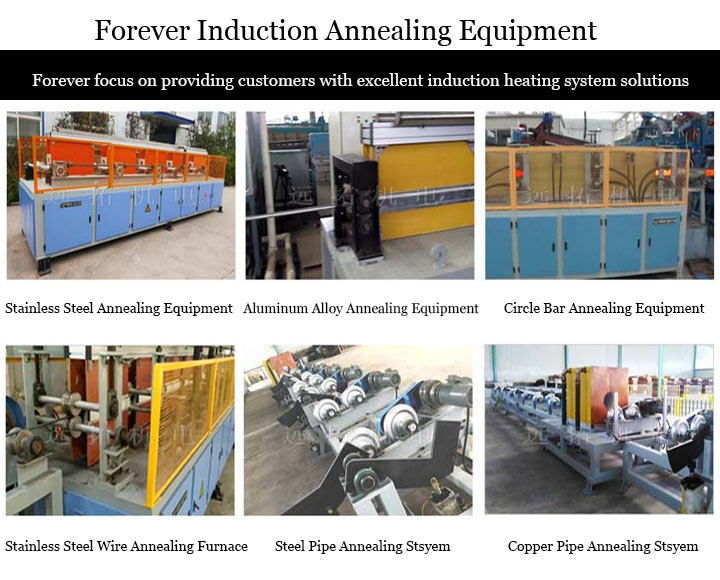

Hebei Forever Electromechanical Equipment Manufacturing Co., Ltd. is a professional manufacturer of seamless Steel pipe induction annealing equipment , steel pipe annealing furnaces, steel pipe continuous annealing furnaces, seamless steel pipe continuous annealing equipment and other pipe annealing furnaces. With rich production experience, Forever has become a technologically advanced enterprise in the industry. Forever seamless steel pipe annealing furnaces have the advantages of low energy consumption, no pollution, safety and reliability, and simple operation. Choosing high-quality seamless steel pipe annealing furnaces, come to Hebei Forever Electromechanical!

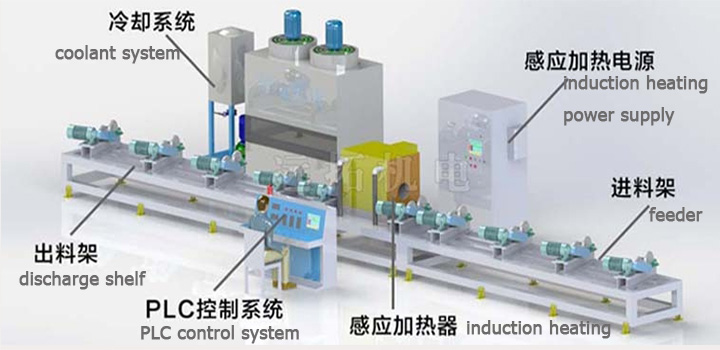

Seamless steel pipes have a wide range of applications. Seamless steel pipes are rolled from ordinary carbon structural steel or alloy structural steel, with a high production capacity, and are mainly used as pipelines or structural components for transportation. The Stainless steel pipe induction annealing equipment produced by our company is controlled by an energy-saving power supply. The KGPS intermediate frequency power supply adopts a parallel resonance design, phase-shifting and power regulation. The equipment is mature and stable, and has great advantages in a large power range. DSP control, fast capture of phase-locked start, meeting frequent start stop requirements, with a high success rate.

Advantages of seamless steel pipe annealing equipment :

1. The sensor copper tube of the seamless steel pipe annealing furnace is wrapped with T2 oxygen free copper, with a wall thickness of 3.0mm or more. The insulation material of the sensor has high strength, high temperature resistance, and a longer service life;

2. The inlet and outlet ends of the sensor are sealed with 5mm copper plates, which infinitely reduces magnetic leakage and extends its service life.

3. The sensor chassis is made of high-strength aluminum alloy to reduce the impact of magnetic leakage and heating on other components. A water-cooled roller is installed between every two sensors, and each roller is equipped with a variable frequency speed control motor.

4. The roller conveyor between the furnace bodies is made of 304 non-magnetic stainless steel and water-cooled. The feeding system of the seamless steel pipe continuous annealing equipment is driven by an independent motor reducer for each shaft, controlled by an independent frequency converter, and flexibly designed with speed difference output. The operating speed is controlled in segments.

5. The control of induction heating equipment is proficient, with a strict level management system and a comprehensive one click reduction system.

6. Language switching can be provided according to different countries and regions.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 06-21-2024