When it comes to Metal induction heat treatment furnace, at present, heat treatment manufacturers generally choose induction heating equipment, the reason is because of the unique heating mode of induction heating equipment, heating environmental protection, intelligent production, heating efficiency and so on. And become one of the best selection equipment of major heat treatment manufacturers.

The performance characteristics of induction heating equipment are as follows:

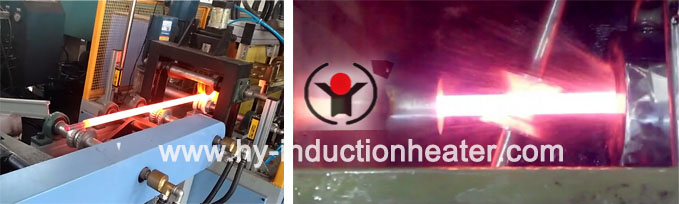

1. The heating mode of induction heating equipment is flexible, which can quench the surface of metal workpiece, or carry on the whole diathermy treatment, or local and integral heating. The local heating efficiency is higher and the energy saving is more energy, and the deformation degree of the workpiece is also small.

2, compared with other heating equipment, the induction heating equipment does not need gas protection to heat the metal, the heating speed of the metal workpiece is faster, and the surface does not produce oxidation scale and decarbonization. The user can adjust the power and frequency of the equipment according to the need, and control the production of the equipment.

3, the induction heating equipment is equipped with a temperature control system to monitor the heating temperature of the workpiece in real time, and the power of the power supply is automatically adjusted by the temperature control system. Ensure that the heating temperature of the workpiece is uniform and the temperature difference of the core table is small.

4, the intermediate frequency heating equipment can form a continuous production line with other mechanical equipment, the degree of mechanization and automation is high, it is easy to centralized management, and the cost of manual transportation is reduced.

5, The induction heating equipment can be used for quenching, annealing, quenching and tempering, etc., according to the size and shape of the user’s workpiece and the production requirements of the induction heating equipment. According to the different dimensions of the user’s workpiece, the furnace body of the corresponding specification can be configured, and the remote extension electromechanical adopts the assembled sling structure, which can only be produced by connecting the water and electricity joint, and the furnace body can be replaced simply.

6, the charging rack and the blanking rack can be arranged according to the requirements of the user, etc. Realize automatic production, reduce manual feeding and unloading, simple operation.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 05-24-2019