With a professional R & D team, Forever factory can provide suitable solutions for different work piece induction heating production line at reasonable prices according to the actual needs of different customers and requirements. Our focus is supplying the most economical automatic heating production line to achieve high efficient production in your plant with advanced induction heating technology and powerful after-sales service.

What can Forever induction heating equipment heat?

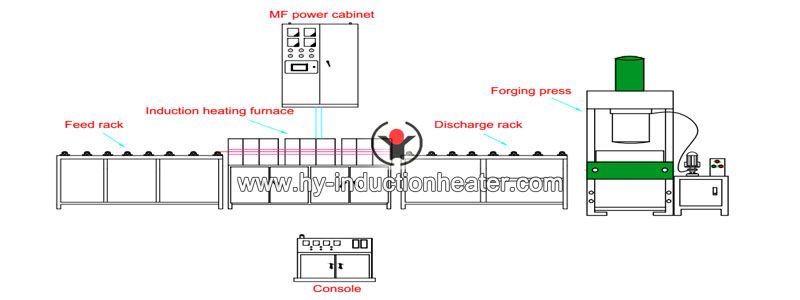

Automatic induction forging production line

Automatic forging production line includes automatic feeder, induction heating equipment,temperature control system, IF power supply, remote console. We have rich experience in manufacturing automation of hot forging production line which is widely used in automobile and hardware industry. At present, our intelligent control system of console can reduce the technical requirement of operator and ensure the process repeatability.

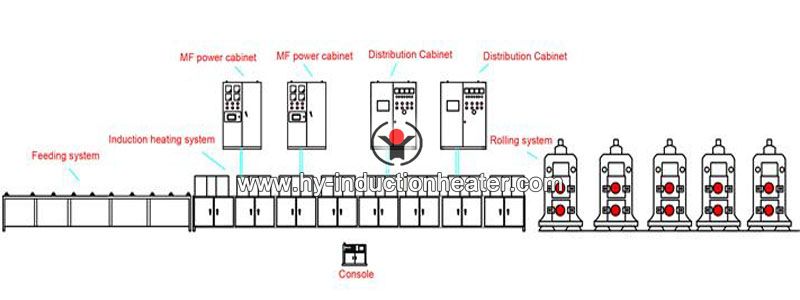

Billet inline heating production line for hot rolling

Steel billet heating furnace is an important process in hot rolling production,which has direct influence on equipment stability, billet heating quality, power consumption and production capacity. Our billet heating furnace can satisfy different diameters of billet heating and different production capacity.

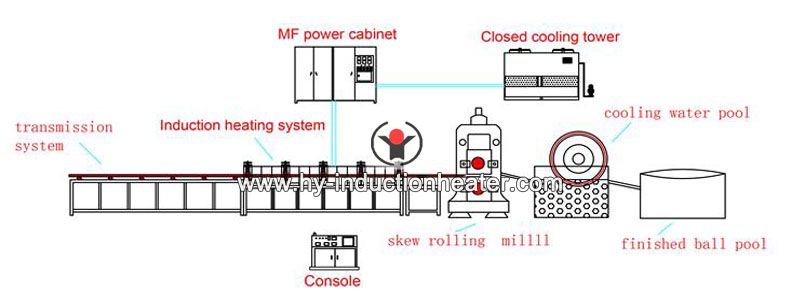

Steel ball hot rolling production line

As the new technology of steel ball production, skew rolling process has replaced traditional casting and forging process gradually.Our steel ball hot rolling production line is using electric furnace to heat steel bars and and bars will be sent to rollers by transmission device. The roller will rotate and skew roll to balls, which is driven by motor and reducer motors.This production line can ensure the steel ball quality stability to the maximum extent. The steel balls has good features of accurate size, good roundness, high hardness and good mechanical properties.

Skew rolling process does not need cutting material and air hammer forging, which increase production efficiency greatly and reduce labor intensity.

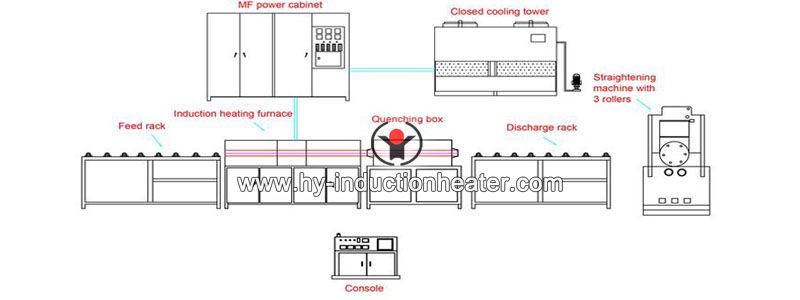

Induction quenching production line

Induction quenching production line can not only used for surface quenching for work piece but also used for inner wall quenching.The traditional heat treatment can not meet the requirement.

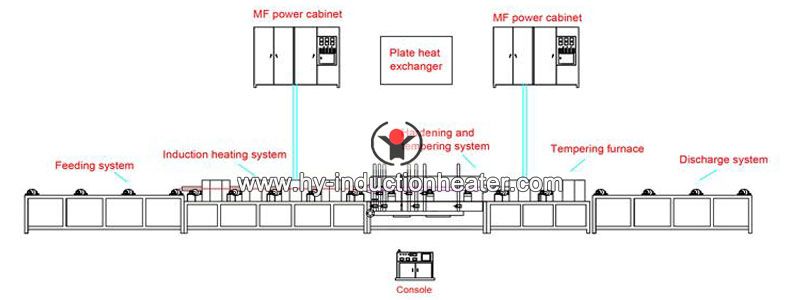

Hardening and tempering production line

Forever hardening and tempering production line is mainly used for hardening and tempering steel. The hardening temperature is usually 850 ℃, and the tempering temperature is usually 650℃.

Our quenching and tempering production line includes storage rack,hardening feeding machine,quenching heating module, quenching discharging machinery, straightening machine, water cooling system, tempering feed machinery, tempering heating module, holding module, tempering discharging machinery, discharge rack.This production line has rational man-machine interface, full PLC automatic control & IPC module.

Forever induction heating system has the function of process parameters record, inquiry and print; Automatically adjust heating temperature;Real time monitoring and display the parameters of the electric furnace; Automatic prediction of failure and alarm; remote control for the electric furnace; automatic various reports for production.