Induction Quenching is a process of heating followed by cooling generally fast to improve hardness and mechanical strength of medium carbon or medium carbon alloy steel. Surface quenching process can increase the surface hardness, wear resistance and fatigue strength of the workpiece, while the core part retains a certain degree of plasticity and toughness.

According to the different heating methods, surface quenching can be divided into induction heating (high frequency, intermediate frequency, frequency) surface quenching, flame quenching, electrolyte heating surface hardening, laser heating surface quenching and electron beam surface hardening. At present, induction quenching is the most common used.

Induction quenching

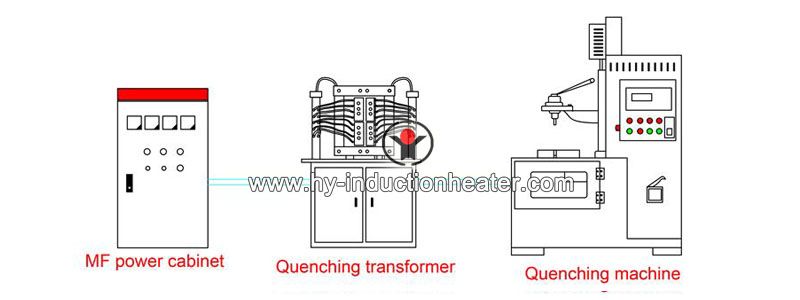

Guide rail induction quenching machine

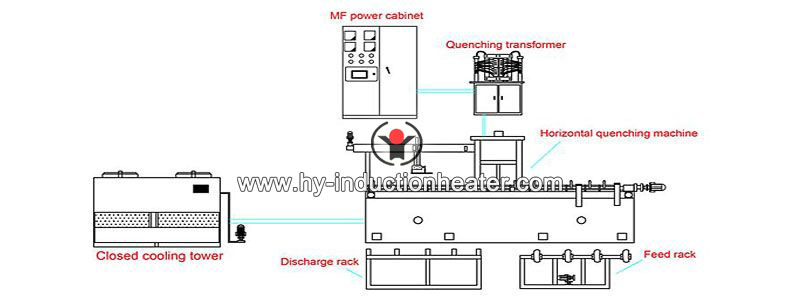

Shaft horizontal induction quenching machine

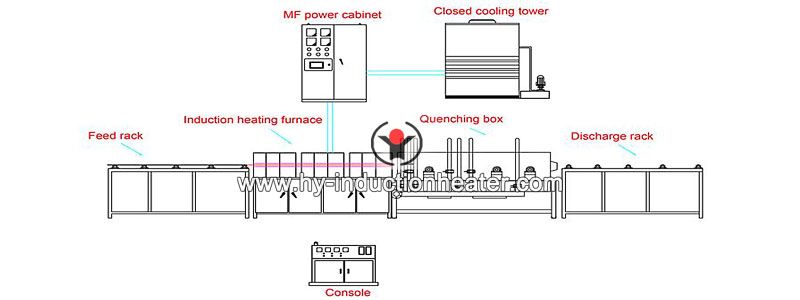

Steel pipe surface quenching production line