Induction forging furnace

Features:

Application: Forging & Forming

Material Heated:Carbon Steel & Alloy Steel

Diameter Allow: Φ20-300mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

Forever Induction forging furnace offer high efficiency and energy saving especially for the forging industry where the induction heater is used to pre-heat metals to between 1100 and 1200 degrees C (2010- 2190F). This increases their malleability and also aids flow in the forging die. Precise control of the heating temperature can also improve the result of heat treatment after forging. Our Induction forging furnace have pre-stressed structures, high strength, long life and easy maintenance.

Induction forging furnace consists of:

● Medium frequency power 160KW-8000KW

● Compensation capacitance and forging working station

● Induction coil

● Pneumatic feeding mechanism

● Plate heat exchanger or closed cooling machine

Induction forging furnace features

● Forge furnace with high heating speed

● Oxidation with less decarburization

● Energy saving, less pollution

● High degree of automation, full automatic operation can be realized

● Heating temperature uniformity, high control precision

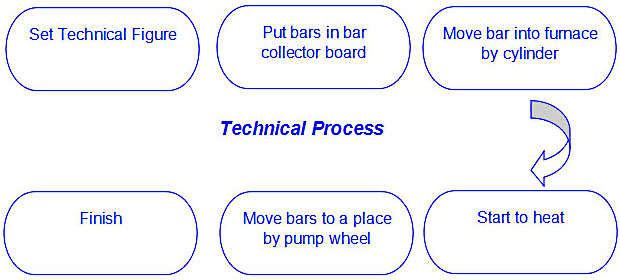

Technical process of forging round bar furnace:

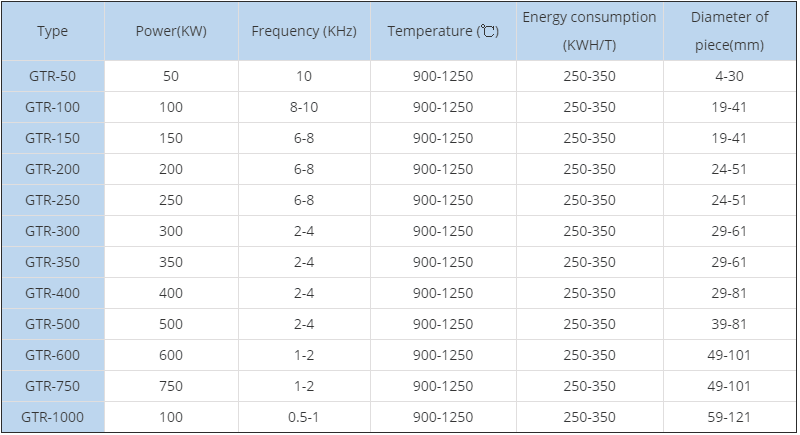

Technical parameters

If you have any inquiry about quotation or cooperation,please feel free to email us at tom@foreverfurnace.com . Our sales representative will contact you within 24 hours. Thank you for your interest in our induction heating equipment .

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.