Induction bar heater

Features:

Application: Forging , Rolling & Quenching

Material: Carbon steel, Brass,Iron,Alloy steel,Stainless steel,Aluminum

Diameter Allow: Φ20-300mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

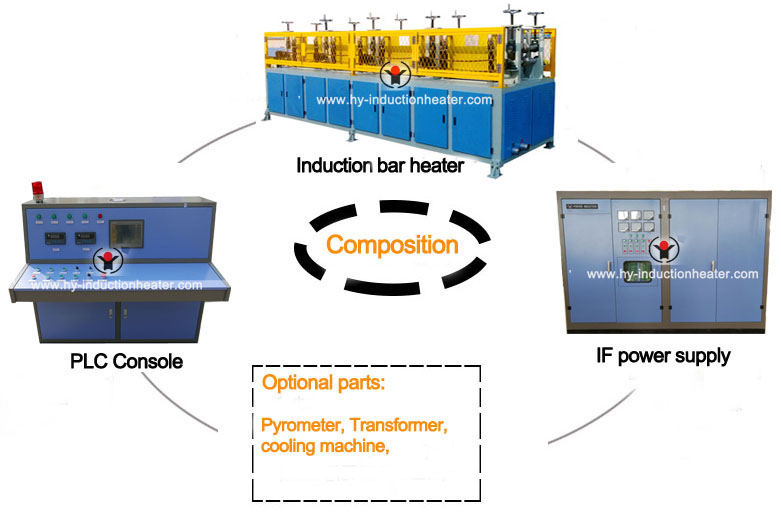

Customized Induction bar heater

Inductive heating is efficient, easily controlled, uses no energy when not heating, and puts the heat where you want it, when you want it. No idle time, no massive refractories to heat, and close coupling enables you to use energy in the best possible way.

Induction bar heater working process:

Bar automatic feeder—Bar induction heating—Automatic discharging—Forging or Rolling

Bar automatic feeder—Bar induction heating—Water cooling—Bar induction tempering—Automatic discharging

NEW TYPE POWER SUPPLY

● Power saving 10% -15%:No harmonics, high power factor, load output voltage is high, the load coil current is low,small power consumption.

● Using special transformer for electric furnace

● The furnace has high reliability: This product uses the latest DSP control technology, with reasonable structure, easy commissioning & reliable performance, which has automatic protection functions including water temperature, water pressure, phase shortage, over-current, under-voltage to ensure The product is running in stable and reliable condition

● Adopt famous brand components which reduce fault rate and make sure the equipment can run reliably, thereby reducing the shutdown probability caused by failure.

● Advanced technology & Easy maintenance: Having simple structure,perfect protection for control circuit & the most advanced touch screen control, our power supply can show complete failure and find the error.It adopts DSP control technology, which has a high processing speed, which ensures the efficient and orderly operation of the device functions. real-time computing function and real-time simulation and simulation capability.

Quality assurance measures

● Fine Design

Forever has provides induction heating equipment for hundreds of users at home and abroad, all the design drawings are made with computer.

● Working with reliable supporting accessories manufacturers

The main supporting parts are from fixed manufacturers, a variety of electrical pneumatic components are from domestic well known brand products,especially PLC and low-voltage electrical relays adopts SIEMENS brand. In addition, in order to ensure the quality of accessories, our company arranged designer and engineer to be involved in the main parts selection.

● Strict process inspection and quality inspection

Following ”survive with high quality,develop with credibility “guidelines, our company arranges the technicians to enrich the production management, technology & quality inspection departments, strengthening the inspection process to ensure the quality of the product.

Successful cases

| Bar Diameter | Bar Length | Heating Temp. | Power |

| Ø 16 mm | 300mm | 950℃ | 250KW/4000Hz |

| Ø 31-80 mm | 70-480mm | 1250℃ | 500KW/2500Hz |

| Ø 120 mm | 1500mm | 1250℃ | 2000KW/1000HZ |

| Bar Diameter | Bar Length | Heating Temp. | Production capacity |

| Φ36-45mm | 1500mm | 1125°C ± 25 | 3T/H |

| Ø60mm | 6000mm | 1200℃ | 4.4T/H |

| Ø70mm | 6000mm | 1200℃ | 5.3T/H |

| Ø80mm | 6000mm | 1200℃ | 6T/H |

As our induction heater is all customized, the above parameters are only for your reference.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of heat treatment furnace in China; Glad to be your business partner in induction heating field.