Forging tube

Features:

Application: Forging & Forming

Material Heated:Carbon Steel & Alloy Steel

Diameter Allow: Φ20-300mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

Forging tube induction furnace

Induction heating is the process of heating an electrically conducting object (usually a metal) by electromagnetic induction, through heat generated in the object by eddy currents (also called Foucault currents).

Forever forging tube induction furnace is specialized used for tube heating before forging.

The basic component of tube forging induction heating system is an AC power supply, induction coil and tube (material to be heated or treated). The power supply sends alternating current through the coil, generating a magnetic field. When the tube is placed in the coil, the magnetic field induces eddy current in the tube, generating precise amounts of clean, localized heat without any physical contact between the coil and the tube.

Forging tube induction furnace advantages

● Fast heating speed, less oxidation decarburization

● High degree of automation, which can realize full automatic operation for hot forging.

● Uniform heating, high precision of temperature

● Simple induction furnace replaced

● Low energy, no pollution

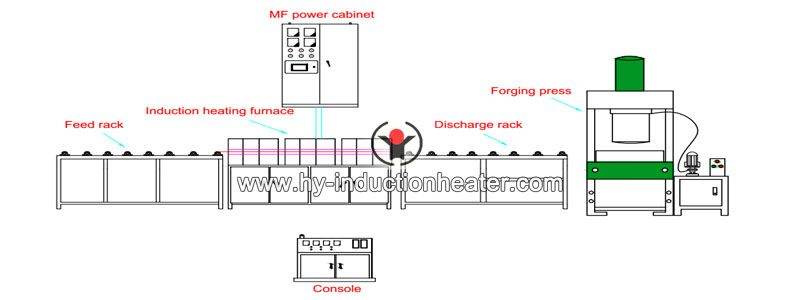

Forging tube induction furnace working process

Manually put tubes in the automatic feeder—feeding tube into furnace—Induction heating tube as set parameters—Automatic chain discharging tube

As our induction heating equipment is customized, so please tell us the tube diameter, length and production capacity,then we will provide most economic proposals.

If you need tube forging induction heating furnace please send us inquiry at

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.