Drill pipe quenching tempering

Features:

Application: Quenching & Tempering

Material Heated:45#,40Cr,42CrMo,65Mn

Diameter range: ø10-120mm

Heating way: Induction heating

Product Detail

Application Video

Product Tags

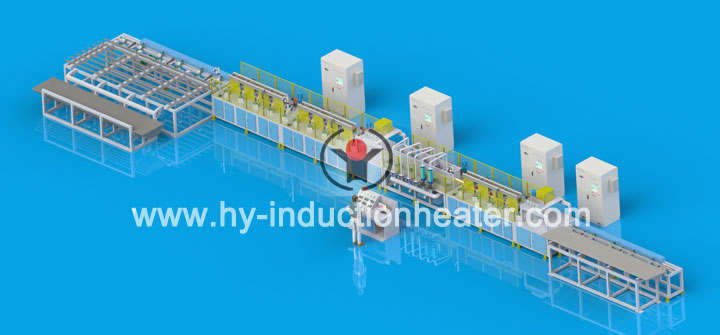

Drill pipe quenching tempering line

● Product name:Drill pipe quenching tempering line, Drill pipe induction heat treating line

● Diameter range: Not limited

● Product strength: Uniform quenching & tempering, less oxidation, high efficient, import components

● Cooling way: Spray cooling

In the years of oil drill pipe heat treatment equipment experience, our company has designed a large number of medium frequency induction heating quenching and tempering production line, petroleum machinery (drill pipe, drill collar, sleeve, sucker rod etc.) heat treatment lines for users, which is according to the induction heating advantage, combined with the traditional process. Much practice proves that our heat treatment line can improve productivity greatly and reduce power consumption by 20%, which makes our customers become more competitive.

Advantage for Drill pipe quenching tempering line

● Using embedded computer monitoring system, the two closed loop temperature control, our drill pipe quenching tempering line has function of automatic thermostat control. As long as the temperature is set, no need worker to be involved.

● The roller conveyer control is divided into three groups: Control for feeding; control for inductor group; control for discharding.which is conducive to the continuous heating to avoid gap between the workpiece.

● Available to set parameters and storage for different sizes of workpiece separately including technical parameters for quenching and tempering, workpiece specifications, setting temperature, roller speed, power and so on. For different workpiece, user only need to select corresponding workpiece number, then we can finish all the parameters setting.

● Related parameters record & storage: Real-time display and record workpiece temperature, spraying water temperature and workpiece & operator No.The user can check and print historical record and curve with historical data browser function. The record can be saved for 3-5 months.You can also transfer to U disk for storage.

● Quenching and tempering conversion IS using electronic control mode, without manual operation.

● Design stainless steel lining in the inductor,which can avoid fault such as workpiece bending or stripping.

● Power factor ≥ 0.96.

● America Raytek thermometer improves the accuracy of temperature measurement.

● PLC is using German Siemens S7 series. Its reliability ranks first in the industrial control industry.

● Complete spare parts and professional after sales service personnel, ensuring timely and thoughtful customer service service.

If you are interested in our induction heating equipment, please send us inquiry at

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.