Sway bar hardening and tempering line

Features:

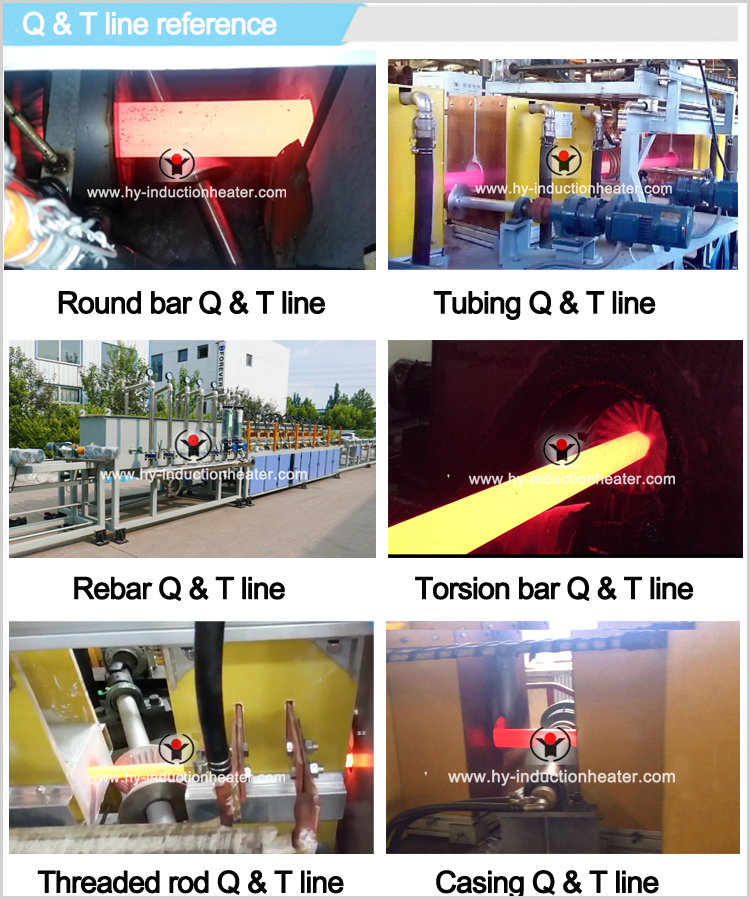

Application: Hardening & Tempering

Material Heated:auto sway bar

Bar Diameter reference: Ø17~Ø24mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

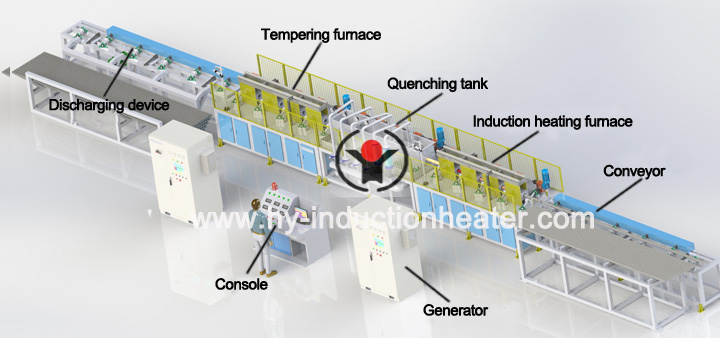

Working principle of Sway bar hardening and tempering line:

The heating method is continuous on-line heating. The complete production line only needs the worker to put the sway bars on the storage table, then other actions will be completed by the system controlled by PLC.

Technical Parameters for sway bar hardening and tempering line

● Steel grade:low alloy steel

● Torsion bar diameter :(Ø17~Ø24)mm

● Bar length : 1005~1167mm

● Productivity: 2-3m/min (ø20 as standard)

● Quenching temperature: 850℃(This temperature can be adjusted as per the actual production status)

● Power required: KGPS100KW

● Frequency required: 2000~3000Hz

Features for sway bar hardening and tempering line:

1.Auto sway bars is driven by frequency control motor for feeding, which is in uniform speed transportation while self-rotating. We set inductive position detecting device in the transportation line to ensure the sway bar ends through the roller smoothly. The production line set various position sensing device and stall detection to ensure the whole line can be safety running .

2.Automatic uploading: feeding and unloading platform adopts high quality steel welding firm which can withstand impact load.

3. The frame of the transmission mechanism has enough strength and rigidity. In order to facilitate the installation of the equipment, the bottom of the frame has equipped with adjustable foot , so that the whole of the equipment is more beautiful.

4.According to the safety standardization requirements of the machinery industry, all mechanical rotating exposed parts are equipped with reliable protective covers, and the production line shall meet the national environmental protection standards.

5.The power supply adopts the components of famous brands both at home and abroad to ensure reliable operation and low failure rate. The intermediate frequency power supply has the functions of water temperature, water pressure, short circuit and loss of voltage protection.

6.After the sway bar induction heat treatment furnace finish production, we will help users to input the technical parameters for the sway bars hardening and tempering. The operator can select corresponding recipe to start the system, which will be running as the setting parameters. The production parameters can be called at any time, for example, you can call the yesterday’s parameter and produce.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of billet induction heater in China; Glad to be your business partner in induction heating field.