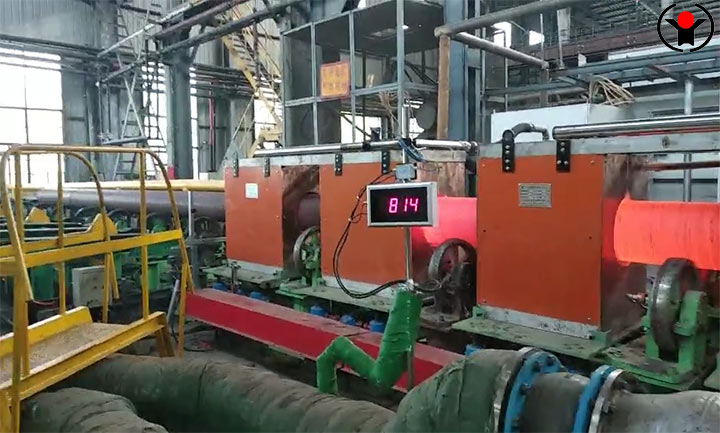

Steel pipe heating and spraying production line

Features:

Power: 200kw-1200kw

Speed: 20-200m/min

Features: Fast heating speed, precise temperature control, minimal thermal radiation and noise, improving product quality.

Product Detail

Application Video

Product Tags

Forever Electromechanical Equipment Manufacturing Co., Ltd. specializes in the production of energy-saving, efficient, and durable Steel pipe heating spraying production line . The professional design and production process of the steel pipe heating and spraying production line, constantly exploring and innovating, putting integrity first, accelerating technological innovation, and improving product grade. The steel pipe heating and spraying production line is affordable and stable in performance. If you purchase the steel pipe heating and spraying production line, come to Forever. You are satisfied with your choice, We are dedicated to providing you with high-quality medium frequency induction heating equipment services.

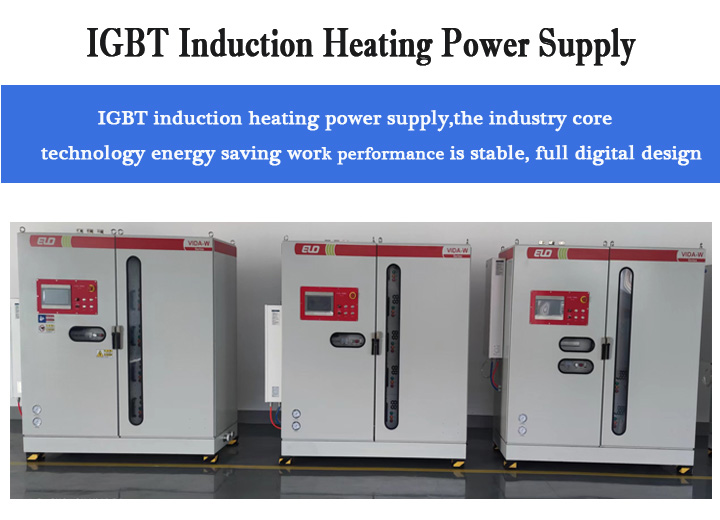

The steel pipe heating spraying equipment adopts intelligent induction heating power control characteristics:

Parallel resonance design, phase shifting and power regulation, mature and stable anti-corrosion equipment for steel pipes; More advantageous in the high-power range above 3000KW.

DSP control, fast capture of phase-locked start, meeting frequent start stop requirements with high success rate.

Variable frequency and load adaptive, with a frequency adaptation range of 200-10000Hz. The induction furnace can be replaced and automatically matched without any manual adjustment.

The steel pipe heating equipment cabinet adopts T2 purple copper bars, which have been sandblasted and passivated; Low leakage inductance, antioxidant, effectively reducing line losses.

Full touch screen control, pure digital tuning, with complete process records and strict level permissions. The main parameters can be restored to factory settings with just one click.

The power supply has a single machine power of 50-600KW and a frequency of 200-10000Hz.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.