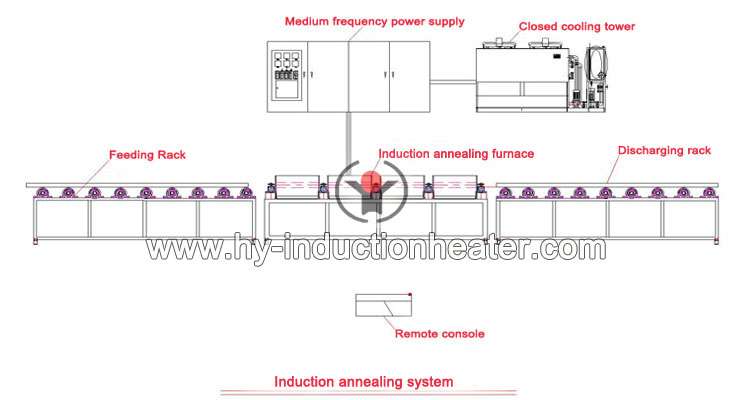

Steel pipe annealing system

Features:

| Application | Steel pipe, pipeline, oil pipeline annealing and hardening |

| Power | 100KW-8000KW |

| Non standard | Professional customization |

| Temp.control | Infrared thermometer |

Product Detail

Application Video

Product Tags

Product Name:Steel pipe annealing system

Typical application:

Steel billet continuous casting and rolling is non-standard product, so please provide the steel billet width,length, thickness, heating temperature and production capacity, then our engineer team will give you the high efficient technical solution and price.

Steel pipe annealing system features

● Power supply system: KGPS500KW/500HZ.

● Transmission roller table: The angle between roller axis and work piece axis is 18 ~ 21 °. The work piece is rotating and go forward at the uniform rate for uniform heating. Rollers between furnace are 304 non-magnetic stainless steel and water-cooled.

● Feeding system:Independent motor reducer drive for each axis, independent inverter control; flexible design speed differential output, section speed control.

● Temperature closed-loop system: Annealing process has stringent temperature requirements, so we make use of Raytek two-color pyrometer and Siemens S7-300 which consist of precise control system, controlling the annealing tapping temperature at 10 ℃ or less.

● Recipe management function: Powerful recipe management system–after inputting parameters of steel grade, outer diameter and wall thickness, this system can automatically call relevant parameters, no need to manually record, check, input required parameters for various work piece.

● Parameters security function: Customer has special confidentiality requirements for their factory workers and visitor, so our control system has multi-level management function. The user can switch the main parameters and particular code flexibly as per authority level.

Forever main pipe induction heating equipment: Steel pipe annealing system, pipeline normalizing and annealing line, oil pipeline seam welding equipment, pipe bright annealing furnace, steel pipe quenching and tempering system.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.