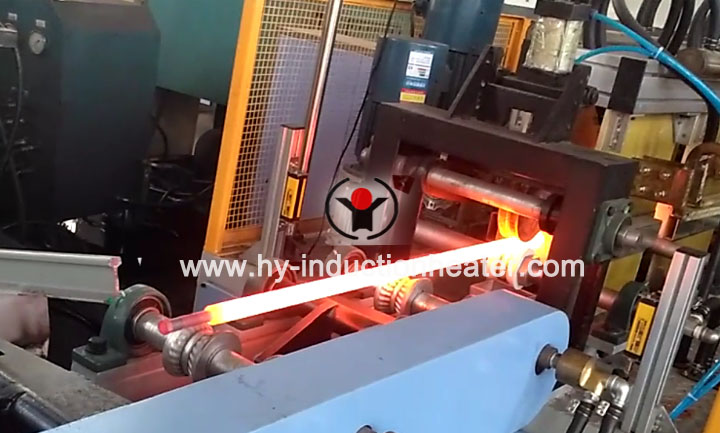

Screw rod hardening and tempering furnace

Features:

| Material | 40Cr, 42MnVB, (65Mn) |

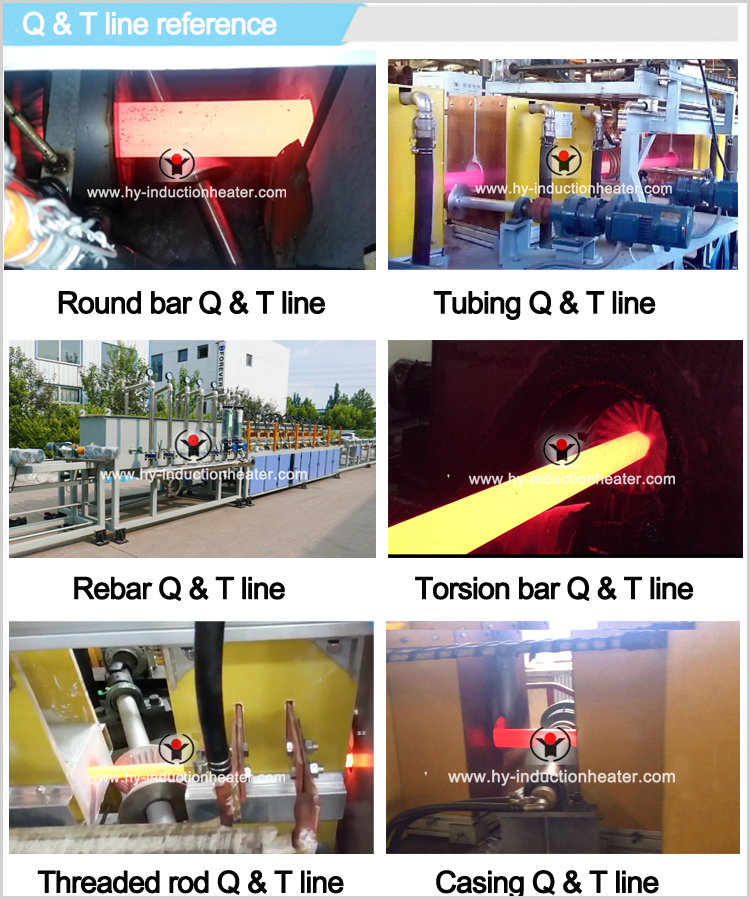

| Suitable for | Screw rod, torsion rod,short bars |

| Process | Hardening and tempering |

Product Detail

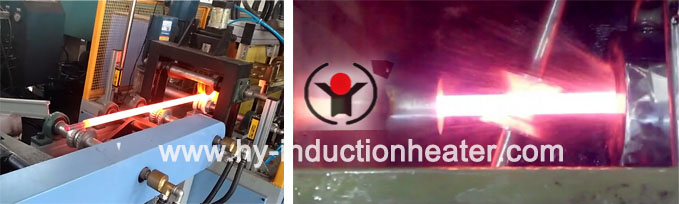

Application Video

Product Tags

Forever is specialized in manufacturing screw rod hardening and tempering furnace, screw rod hardening furnace for 14 years in China. Using advanced induction heating technology and mature hardening and tempering process, our screw rod hardening and tempering furnace has achieved automatic production with high efficiency.

Basic information for screw rod hardening and tempering furnace

| Material | 40Cr, 42MnVB, (65Mn) |

| Suitable for | Screw rod, torsion rod,short bars |

| Efficiency | Customized |

| Process | Hardening and tempering |

Screw rod hardening and tempering furnace features:

1. Screw rod induction heat treating furnace adopts intelligent series resonant intermediate frequency power control, and the starting success rate can reach higher.

2. The rectification power factor is greater than or equal to 0.96

3.Set temperature interface to achieve temperature closed-loop control.

4.Available to achieve manual/automatic switch and local/remote switch.

5.For different size of screw rod, we will equip different induction heaters to be suitable. The power supply parameters can be automatically adapted to the load without manually adjusting.

6.Digital setting for all the parameters has completely solved the problems of the temperature drift brought by previous analog line potentiometer and strong randomness. After putting into the market, the effect is good and is well received by the customers.

7.The water cooling system consists of thyristor power supply cooling, induction coil cooling, capacitor cooling, roller cooling, pump motor and water tank.

8. Low loss for shutdown, small reactive component, low loss of slot, saving energy 10-30% compared with traditional parallel inverter power supply.

| Diameter | Automatic Control | Power Design |

| Ø18-Ø28 mm(bar) | PLC Control | IGBT200KW Hardening |

| Ø30-Ø70mm( bar) | PLC Control | KGPS350KW Hardening |

| Ø80-Ø110( bar) | PLC Control | KGPS450KW Hardening |

| Ø16-Ø32 mm(rod) | PLC Control | IGBT200KW Hardening |

| Steel bar diameter | Automatic Control | Power Design |

| Ø10-Ø28 mm | IPC Control | KGPS350KW Quenching+KGPS160KW Tempering |

| Ø42-Ø48 mm(Anchor Bolt) | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-60 mm | IPC Control | IGBT250KW Quenching+IGBT160KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-Ø110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.