Round bar induction heating furnace

Features:

| Application | Round bar heating, forging, rolling,extrusion |

| Power | 100KW-10000KW |

| Non-standard |

Professional Customization |

Product Detail

Application Video

Product Tags

Product Name: Round bar induction heating furnace

Typical Application:

Forever commitment:No matter what the work piece is round bar, steel bar, steel pipe, aluminum bar,steel billet,or special work piece annealing,quenching or partial heating,diathermy, continuous induction hot rolling—We will design and manufacture the induction heating equipment to satisfy your requirements.

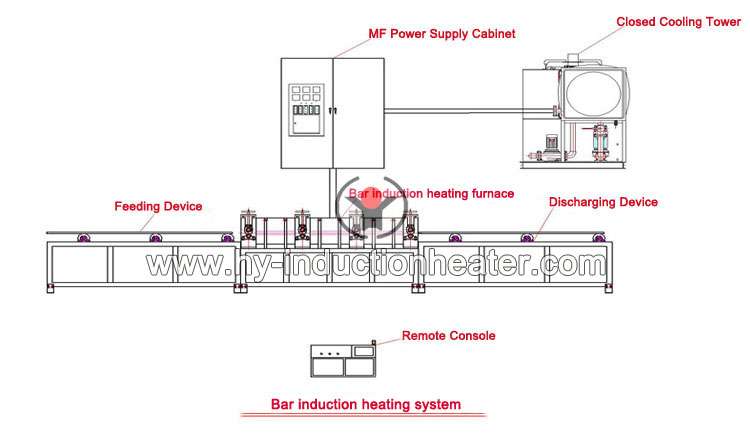

Bars induction heating system layout

Frequency selection for round bar induction heating furnace

| Frequency(Hz) | 300 | 500 | 1000 | 2500 | 4000 | 6000 | 8000 | 1000-15000 | 15000 |

| Round bar diameter(mm) | 160 | 70-160 | 55-120 | 35-80 | 30-50 | 20-35 | 15-40 | 10-15 | <10 |

| Slab thickness (mm) | 160 | 65-160 | 45-80 | 25-60 | 20-50 | 20-30 | 12-40 | 9-13 | <9 |

Main features for round bar induction heating furnace

● High reliability; simple maintenance; perfect automatic protection functions of over voltage, over current, over heating, water shortage and so on.

● Digital automatic control for integrated circuit with manual,manual, automatic, semi-automatic control function.

● Automatic frequency tracking; power stepless adjustment; operator can master is within 10 minutes.

● Low power consumption.Saving electricity 40-60% than electrical tube and 20% than SCR.

● Infrared thermometer at the furnace discharging port and Siemens PLC closed loop control.

【Forever】typical induction heat treating equipment:Round steel bar induction heating furnace, steel wire annealing heating equipment, pipeline seal welding equipment, aluminum bar induction heating system, steel ball forging equipment.

Welcome to visit our website: http://www.hy-inductionheater.com/

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.