Bar induction quenching furnace

Features:

Application: Quenching & Hardening

Material Heated:45#,40Cr,42CrMo,65Mn

Heating way: Induction heating

Product Detail

Application Video

Product Tags

Long bar induction quenching furnace

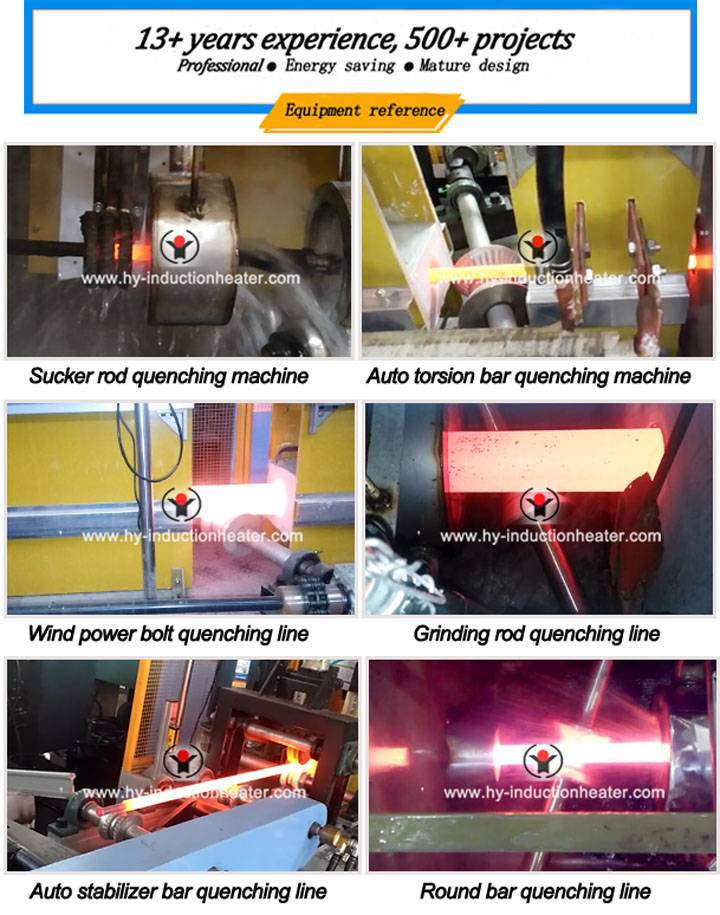

Forever steel bar quenching furnace adopts induction heating as heating method, water cooling system and Siemens PLC control system. So far, Forever has already had many successful cases for quenching furnace, such as shaft quenching furnace, squre pipe quenching furnace, torsion bar quenching furnace, long bar quenching furnace etc.

● Product name: Quenching furnace for steel

● Application: Used for heat treatment for long bar, tube, casing, suction rod, drill pipe, plate, blade etc.

Quenching furnace advantages

● Accurate temperature monitoring & control.

● Inverter efficiency of 92%

● Full programmable speed control for all material handling devices

● Fully automated quick-change lines available

● Recipe driven algorithms enable low quantity orders and small batch processing

● Automatic steel bar quenching furnace change-over when required

● Instant on/off capability with induction heating equipment

● Optional upset end preheating stations

● Optional infrared camera upgrades

● Capable of seamless and welded tube processing

● Wide variety of materials can be processed from low-carbon steel to martensitic stainless steels

● Software diagnostics provide specific troubleshooting assistance for maintenance technicians

● Local service and spare parts available worldwide

Quenching furnace composition

● Medium frequency induction heating power supply

● Induction heating coils

● Automatic feeding and discharging device

● Remote console

● Closed cooling tower

● Infrared thermometer

| Steel bar diameter | Automatic Control | Power Design |

| Ø10-Ø28 mm | IPC Control | KGPS350KW Quenching+KGPS160KW Tempering |

| Ø42-Ø48 mm(Anchor Bolt) | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-60 mm | IPC Control | IGBT250KW Quenching+IGBT160KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-v110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

| Pipe diameter | Automatic control | Power design |

| Ø95,Ø114 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø73.2,Ø88.9,139.7 mm(Drill pipe) | IPC Control | KGPS500KW Quenching+KGPS100KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-Ø110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.