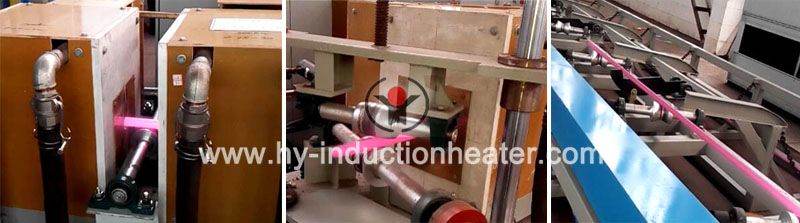

Induction Heat Treatment Machine

Features:

Application: Hardening ,Annealing & Tempering

Material Heated:45#,40Cr,42CrMo,65Mn

Bar Diameter Allow: Φ20-110mm

Pipe Diameter Allow: Φ60-300mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

Product Name: Induction Heat Treatment Machine

Induction heating is the most controllable and energy-efficient way to apply heat during the heat treatment process. Because the technique is non-contact by nature, our induction heat treatment equipment allows for high production rates that meet the most demanding metallurgical requirements. Localized heating and direct magnetic coupling into the part minimizes ambient heat in the local environment, which enhances operator safety and comfort.

We will meet with you to learn more about your production needs, and will then design and build a high-quality, fully automated induction heating solution within your budget that maximizes your output and remains energy efficient.

Heat Treatment Applications:

| ● Axles | ● Sprokets |

| ● Bar | ● Wheel |

| ● Pipe | ● Track links |

| ● Shaft | ● Wire |

| ● Sucker rod | ● Springs |

| ● Drill pipe | ● Gears |

| ● Piston rod | ● Crankshafts |

Advantages

- High efficiency

- Proven & mature Design

- Reduced customer start up time

- Advanced PLC control, power & temperature control

- Quick release connections for both power & water

- All the cables and capacitors are well protected for long life performance

| Steel bar diameter | Automatic Control | Power Design |

| Ø10-Ø28 mm | IPC Control | KGPS350KW Quenching+KGPS160KW Tempering |

| Ø42-Ø48 mm(Anchor Bolt) | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-60 mm | IPC Control | IGBT250KW Quenching+IGBT160KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-v110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

| Pipe diameter | Automatic control | Power design |

| Ø95,Ø114 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø73.2,Ø88.9,139.7 mm(Drill pipe) | IPC Control | KGPS500KW Quenching+KGPS100KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-Ø110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

As our hardening and tempering furnace is all customized, the above parameters are only for your reference.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field