Induction Heat Treatment Furnace

Features:

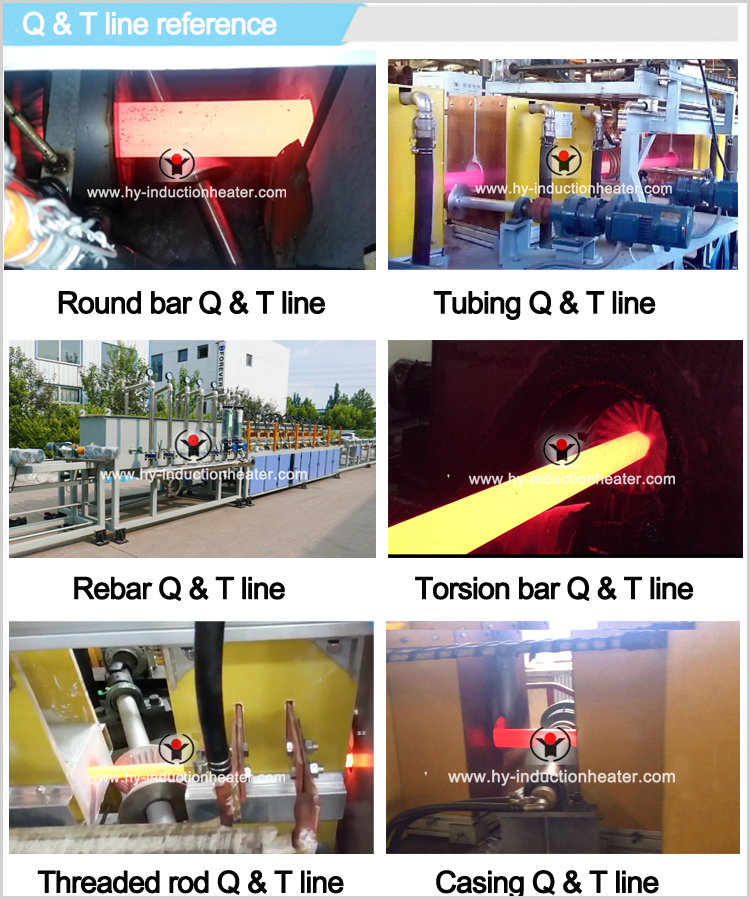

Application: Hardening ,Annealing & Tempering

Material Heated:45#,40Cr,42CrMo,65Mn

Bar Diameter Allow: Φ20-110mm

Pipe Diameter Allow: Φ60-300mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

Product Name: Induction Heat Treatment Furnace

Typical Application:

Induction heat treatment furnaces provide a fast, efficient and economical method of heating any electrically conductive material to a precise temperature. The equipment utilizes clean, readily available electric power to heat the entire surface of the work piece or selected specific areas. Heat depth can be limited to just the surface or can include the entire cross section. Temperatures are accurately controlled to meet the specific requirements of the application. Induction heat treating is equally efficient for job shop or high production operations. Since induction heating is clean and radiated heat is minimized, the process heating system can be installed directly in your production line or general work area. The equipment is compatible with existing in-plant material handling systems, and can be automated to meet specific production requirements.

Benefits

- High reliability:Adopt famous brand components of IGBT power supply which reduce fault rate and make sure the equipment can run reliably.

- Safe and reliable.There are reliable protection covers for the mechanical rotating parts,which is durable and very safe for operators. Automatic protections for water temperature,water pressure,phase shortage,overcurrent and undervoltage.

- Easy installation & commission and simple operation.

- Transmission mechanism frame has sufficient strength and rigidity for ease of installation of equipment

- Feeding and discharging table is using high quality steel welded firmly, which can withstand a certain impact load.

Successful cases

| Steel bar diameter | Automatic Control | Power Design |

| Ø10-Ø28 mm | IPC Control | KGPS350KW Quenching+KGPS160KW Tempering |

| Ø42-Ø48 mm(Anchor Bolt) | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-60 mm | IPC Control | IGBT250KW Quenching+IGBT160KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-v110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

| Pipe diameter | Automatic control | Power design |

| Ø95,Ø114 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø73.2,Ø88.9,139.7 mm(Drill pipe) | IPC Control | KGPS500KW Quenching+KGPS100KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-Ø110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

As our induction heater is all customized, the above parameters are only for your reference.

Welcome to contact us at sales@foreverfurnace.com for more detailed price & solution.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.