Induction Hardening Equipment Manufacturers

Features:

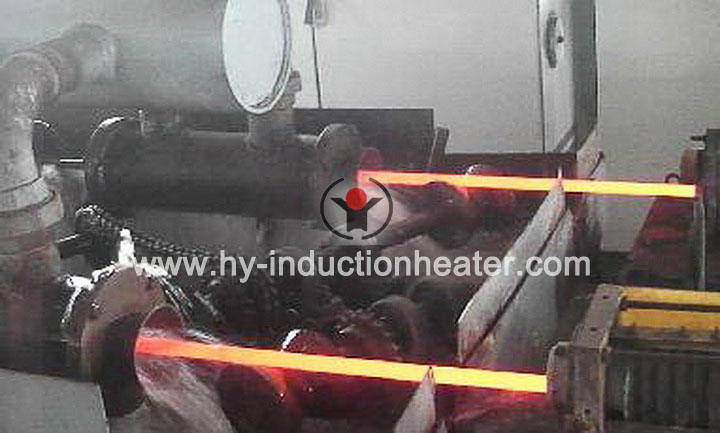

Application: Quenching & Hardening

Heating : Pipe, Tube, Bars,Rods

Diameter Allow: Φ20-300mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

Induction Hardening Equipment Manufacturers

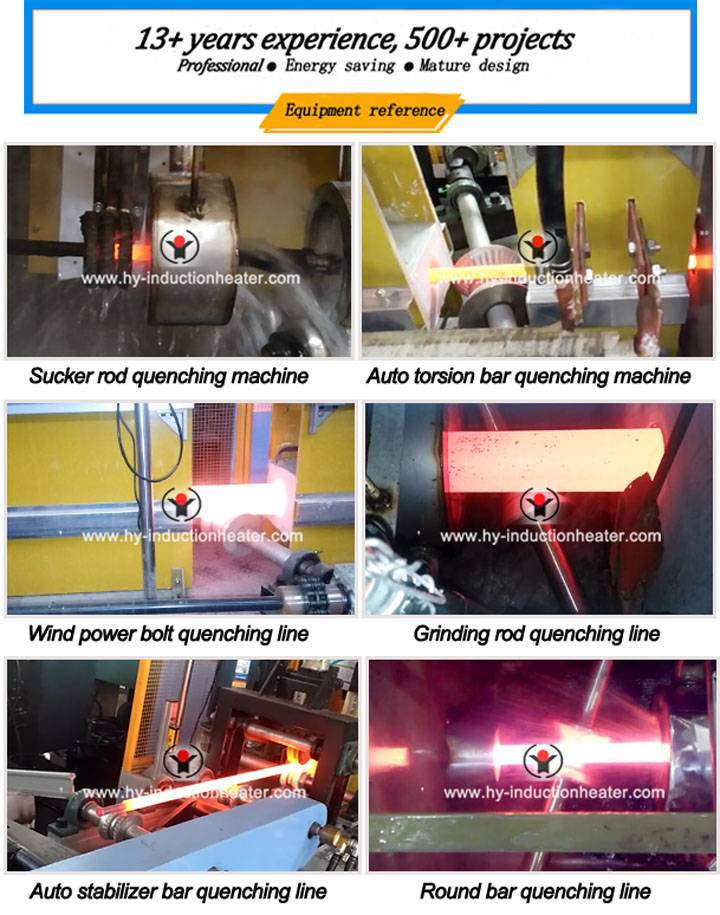

Induction hardening technique (limited to certain high strength alloy steels) that reduces the residual internal stresses and distortion resulting from non-uniform transformation and thermal shock typical of conventional oil quenching.

Our induction hardening equipment is designed & produced as per user’s specific requirements with 100% temperature monitoring and recording.

Features

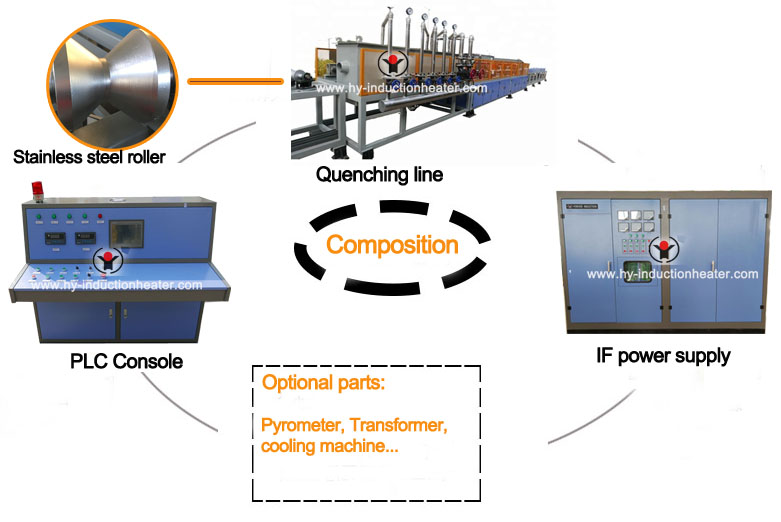

● Manual, semi-automatic and automatic systems

● Optional automatic loading and unloading

● Optional temperature continuous control and monitoring system

● Fast heating, low scale, high temperature uniformity

● Easy exchangeable inductors

● Power 100KW- 8000KW

● PLC controlled

The characteristics of Forever induction hardening equipment are as follows:

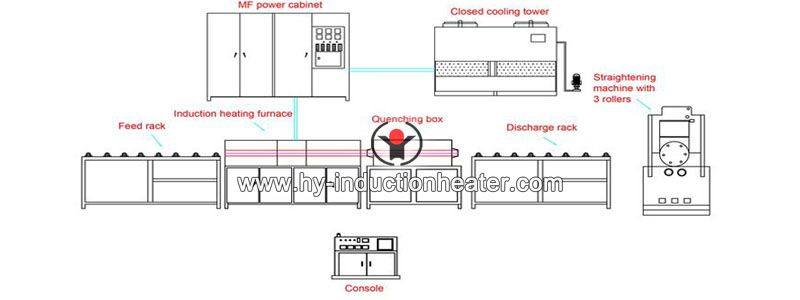

● Online continuous heating, quenching, cooling with high degree of automation. Only two workers can operate complete sets of equipment.

● Adopting electromagnetic induction heating for austenitizing and water spraying cooing, which has higher efficiency than resistance furnace.

● After quenching, the metallographic structure is finer, the mechanical strength is 10-15% higher than that of resistance furnace treatment, and the product has good consistency.

● A complete set of steel bar quenching furnace will be equipped with computer control system, and the power parameters, mechanical parameters, water pressure & flow parameters, heating temperature will be recorded and can be recalled at any time.

● According to different specifications of workpieces and different process requirements, different transmission mode is selected, and the linear speed can be adjusted by frequency conversion to meet the production and straightness requirements.

● The sprinkler system adopts multistage spray cooling, and the pressure and flow rate between the sprinkler rings at all levels can be adjusted.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction billet heater in China; Glad to be your business partner in induction heating field.