IF quenching furnace

Features:

Application: Hardening & Quenching

Material Heated:45#,40Cr,42CrMo,65Mn

Bar Diameter Allow: Φ20-110mm

Pipe Diameter Allow: Φ60-300mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

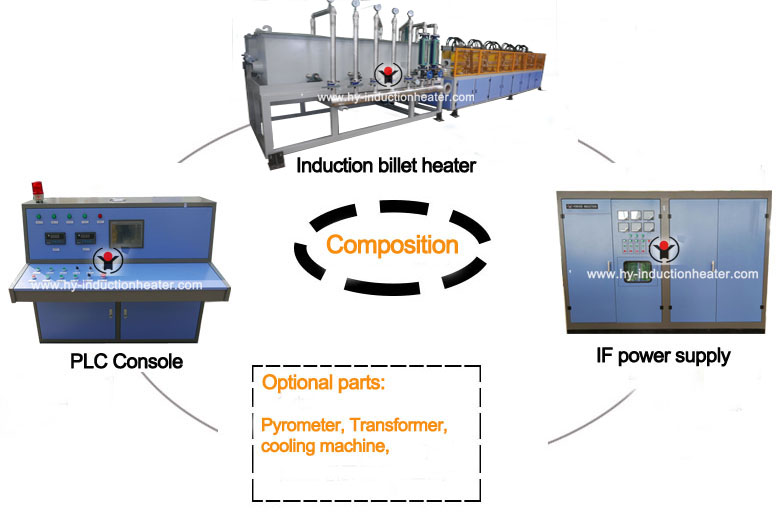

Product Name:IF quenching furnace

Typical Application:

IF induction quenching furnace is used to increase hardness and mechanical strength of steel in a specific area. Steel material will be heated to a temperature slightly higher than the upper critical (between 850-900ºC) and then cooled very quickly in a quenching medium such as oil, air, water etc.

Types for IF quenching furnace

- Case quenching

- Surface quenching

- Through quenching

Applications for IF quenching furnace

- Sucker rod horizontal induction quenching machine see video

- Drill pipe,drill rod induction quenching see video

- Long bar induction quenching see video

- Long shaft induction quenching

- Slab induction quenching see video

- Anchor bolt induction quenching see video

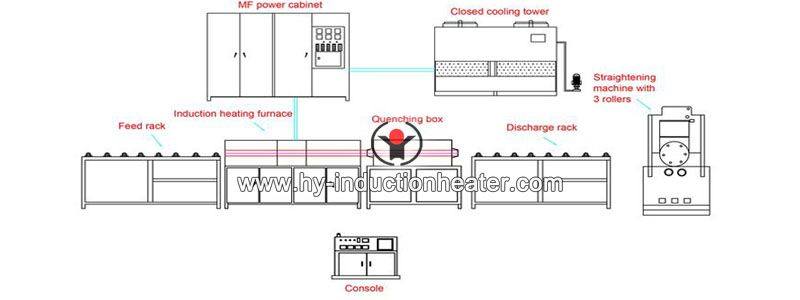

IF quenching furnace process and instructions:

- Material inspection: Mainly check straightness and surface cracks;

- Loading: Generally, the crane will lift the workpiece to the platform and our automatic turning device will turn the workpiece to the roller table for feeding.

- Heating: After setting the heating temperature, PLC automatic control program will control the process;

- Quenching:After setting water flow, pressure and so on, the system will run as the parameters.

- Cool: Cool the quenched workpiece to room temperature;

- Inspect and store the packaging.

| Steel bar diameter | Automatic Control | Power Design |

| Ø10-Ø28 mm | IPC Control | KGPS350KW Quenching+KGPS160KW Tempering |

| Ø42-Ø48 mm(Anchor Bolt) | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-60 mm | IPC Control | IGBT250KW Quenching+IGBT160KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-v110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

| Pipe diameter | Automatic control | Power design |

| Ø95,Ø114 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø73.2,Ø88.9,139.7 mm(Drill pipe) | IPC Control | KGPS500KW Quenching+KGPS100KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-Ø110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

As our induction heater is all customized, the above parameters are only for your reference.

Welcome to contact us at tom@foreverfurnace.com for more detailed price & solution.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.