Automatic steel heat treatment production line

Features:

Application: Quenching & Hardening

Heating : Pipe, Tube, Bars,Rods

Diameter Allow: Φ20-300mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

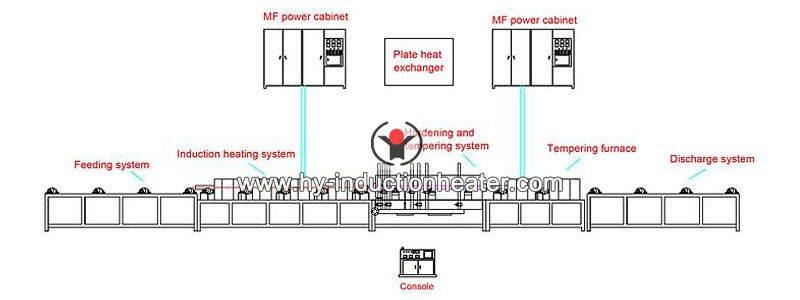

High speed steel heat treatment line

Our High speed steel heat treatment line is designed & produced as per user’s specific requirements with 100% temperature monitoring and recording. The heat treatment process can be quenching, tempering, annealing.

High speed steel heat treatment line working process

During this production line, only need worker to put the work piece on the storage rack, other process will be finished controlled by PLC control, including automatic feeding, preheating, heating, cooling for quenching, tempering, cooling for tempering,discharging, blanking and so on,.This system is intelligent & efficient !

High speed steel heat treatment line features

● Manual, semi-automatic and automatic systems

● Optional automatic loading and unloading

● Optional temperature continuous control and monitoring system

● Fast heating, low scale, high temperature uniformity

● Easy exchangeable inductors

● Power 100KW- 8000KW

● PLC controlled

Successful cases

| Diameter | Automatic control | Power design |

| Ø95,Ø114 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø73.2,Ø88.9,139.7 mm(Drill pipe) | IPC Control | KGPS500KW Quenching+KGPS100KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-Ø110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

As our induction heater is all customized, the above parameters are only for your reference.

If you are interested in our induction heating equipment, please send us inquiry at

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.