Copper tube induction annealing furnace

Features:

Application: Annelaing

Material Heated:Carbon Steel ,Copper material & Stainless Steel

Diameter Allow: Φ20-300mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

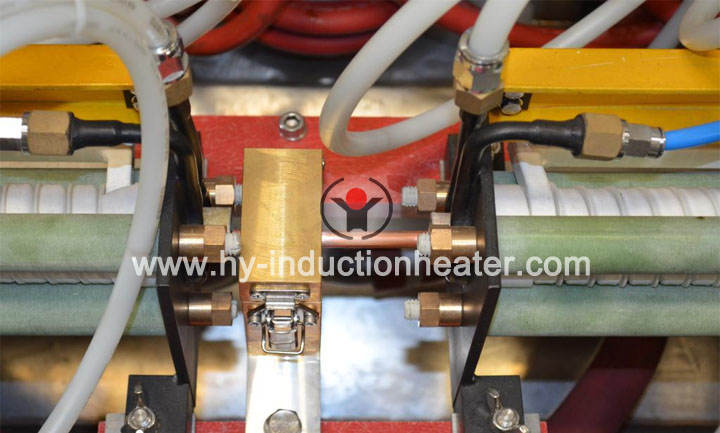

copper tube induction annealing furnace

Copper tube annealing delivers fast, reliable and localized heat, precise temperature control, and easy in-line integration. Each Forever Induction annealing system is built to satisfy specific requirements. At the heart of each system is an Forever Induction control system that features automatic load matching and a constant power factor at all power levels. Most of our delivered systems also feature custom-built handling and control solutions.

Our copper tube annealing furnace is suitable for the follow work piece

| ● Stainless steel | ● Copper pipe, steel pipe |

| ● Steel bar,round bars | ● Sucker rod,drill rod |

| ● Machine guide | ● Seamless pipe,thick-walled pipe |

| ● Casing, tubing | ● Steel wire,steel strand |

| ● Rebar, deformed bars | ● Pipeline |

The technical requirements for Copper tube annealing furnace:

●Tube type: copper tube

● Heating temperature: designed according to specific materials and heat treatment requirements.

●Copper tube annealing equipment configuration and working process: storage platform→conveyor→power cabinet→remote control console→induction heating→medium frequency power supply→receiving

Automatic heat treatment system for copper tube

●Mechanical system: automatic feeding– automatic transportation–automatic heating, automatic discharge. In the whole process, workers are only required to place their tube on platform. Other actions are automatically completed by PLC automatic control system.

●The control system of copper tube annealing furnace: the automatic and accurate closed temperature control system is very important for the heat treatment process of copper tube because the copper tube needs to be heated evenly during the heat treatment process.

Copper tube annealing furnace advantages

● High efficiency

● Proven & mature Design

● Reduced customer start up time

● Advanced PLC control, power & temperature control

● Quick release connections for both power & water

● All the cables and capacitors are well protected for long life performance\

Any inquiry or questions about induction heating equipment, please send us email at

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.