Billet induction preheating machine

Features:

| Used for | Continuous casting billet, small square billet |

| Size | ≥50*50mm |

| Control system | Siemens PLC |

Product Detail

Application Video

Product Tags

Forever billet induction preheating machine has the following applications:

1. Continuous casting and rolling process: After the billet discharging from CCM, the billet surface temperature will reduce before charging the rolling mill. Our billet induction reheating furnace can compensate temperature for the 1/3 of the billet.

2.After initial heating with gas furnace and rough rolling, user can use our billet induction heater to reheat the billet as it’s more flexible than gas furnace.

3.Cold billet heating: If you need to improve the billet production efficiency, you can also use our furnace. Such as from 65T/H to 100T/H and so on. Before your gas furnace, our furnace can be added, this way can match gas furnace and billet induction heater well to achieve the best heating efficiency.

Basic information for stainless pipe hardening furnace

| Material | Carbon steel, alloy steel |

| Brand | Forever |

| Used for | Continuous casting billet, small square billet |

| Size | ≥50*50mm |

| Control system | Siemens PLC |

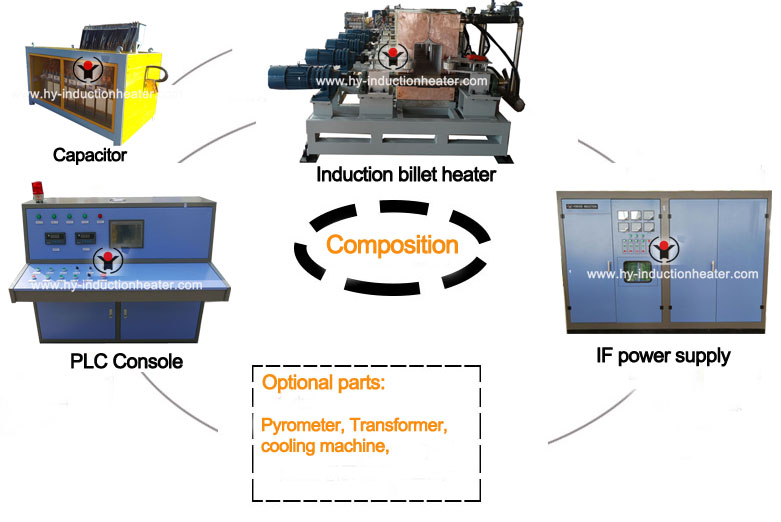

Basic configuration of billet induction reheating furnace:

1.Medium frequency induction heating power

2.Billet induction heater

3.Storage platform and pinch roller automatic feeding device

4.Pinch roller quick discharge device

5.Infrared temperature measurement system

6.Transformer (according to the actual needs of customers )

7. Capacitors (according to the actual needs of customers )

8.PLC operation console

9.Cooling tower

10.Furnace frame (including capacitor, water line, gas line and power line)

Billet induction reheating furnace technical features:

1. The control circuit adopts the fourth-generation control panel (single panel). The main core components are imported integrated circuits. All digital and no relay control circuit makes the entire system stable and reliable.

2. Startup success rate is high.

3.Small harmonics and high power factor.

4.Easy to operate– “fool” type equipment, low maintenance costs.

5.Uniform heating, there is very small temperature difference from the surface to the core and from the head to the tail.

6.Set up power recorder on the power supply, which can display and record the power consumption for each shift.

| Billet size | Billet length | Heating Temp. | Production capacity |

| 60*60mm2 | 3m-4 m | 1000℃-1100℃ | 25T/H |

| 75*75mm2 | 3-6 m | Room Temp.-1100℃ | 25T/H |

| 100*100mm2 | 2 m | 750℃-1000℃ | 7T/H |

| 120*120mm2 | 750℃-1100℃ | 30T/H | |

| 120*120mm2 | 11.5-12.5m | 950℃-1150℃ | 90T/H |

| 125*125mm2 | 6 m | Room Temp.-1200℃ | 8T/H |

| 125*125mm2 | 2 m | 750℃-1000℃ | 7T/H |

| 130*130mm2 | 6 m | 950℃-1150℃ | 50T/H |

| 135*135mm2 | 6 m | 950℃-1150℃ | 100T/H |

| 150*150mm2 | 11.5-12.5m | 950℃-1150℃ | 70T/H |

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.