The Long bar quenching tempering machine manually places the workpieces that need to be heated in a single row and layer on the feeding storage rack. Then, the feeding machinery slowly sends the materials to the feeding rack, and the cylinder pushes the materials into the feeding inclined roller. The inclined roller drives the bar material forward and sends the materials into the quenching heating sensor. Then the workpiece is heated by the quenching heating part, which is divided into quenching heating and quenching insulation heating.

1、 medium frequency induction heating power supply

The complete control system of the intermediate frequency power supply is produced using NASA’s specialized chip technology, and adopts the world’s advanced constant back voltage time inverter control method for frequency automatic follow-up adjustment. The equipment has reasonable wiring and strict assembly processes, with advantages such as complete protection system, high power factor, easy operation and maintenance, and high reliability.

2、 Roller feeder

It mainly consists of a variable frequency motor, a height roller, and a roller assembly. The idler adopts a double seat supported steel roller structure, with high-temperature insulation material filled between the steel roller and the inner sleeve, and the inner sleeve connected to the shaft key. Not only is it easy to disassemble, but it can also prevent surface burns caused by contact with steel rollers during workpiece transportation.

3、 Sensor

The sensor of the bar material quenching and tempering furnace mainly consists of multiple sets of sensors, connected copper bars, water separators (inlet), closed return pipes, channel steel frames, quick change water joints, etc.

4、 Sensor switching (quick change)

1. Switching of group sensors: overall lifting, sliding in positioning installation, quick change connectors for water, and high degree stainless steel bolts for electricity connection.

2. Quick change of a single sensor: Both the inlet and outlet are connected by a quick change connector, and the electricity is connected by two large bolts.

3. Sensor copper tube: all made of national standard T2 purple copper.

5、 The provided rod quenching and tempering production line can meet the requirements of three consecutive shifts of production 24 hours a day, with stable and reliable operation.

6、 There is no sparking phenomenon during the transmission process of the bar material.

The long bar hardening and tempering furnace developed and produced by Hebei Yuantuo Electromechanical is suitable for large-scale repetitive production. Yuantuo Electromechanical’s medium frequency induction heating equipment has a high degree of automation and wide applicability.

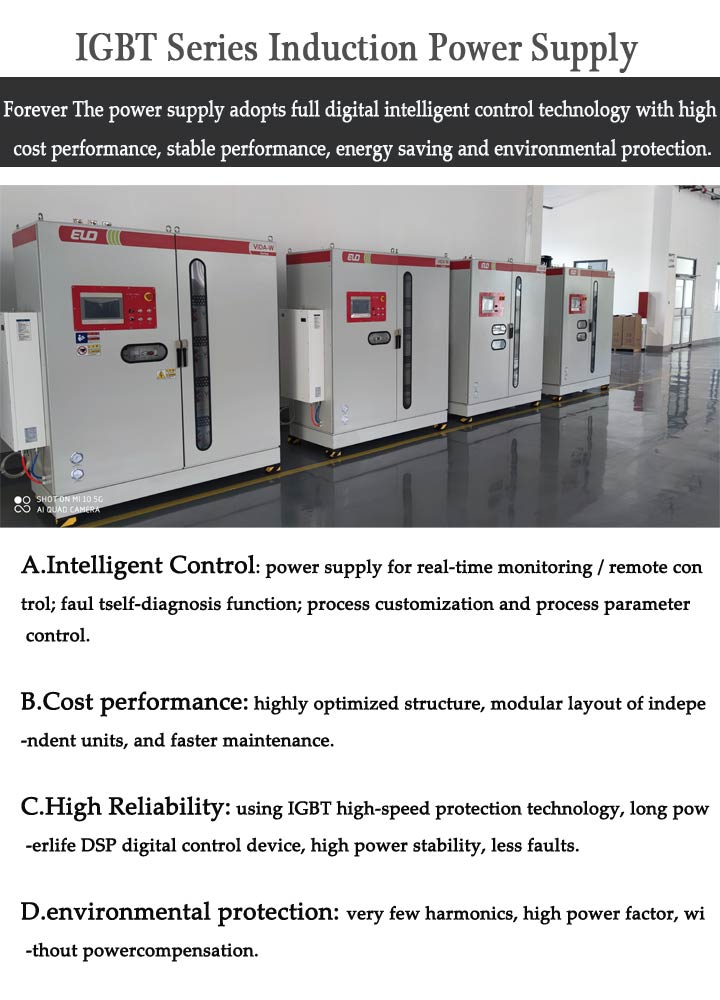

we have IGBT induction heat treatment power supply

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 04-21-2025