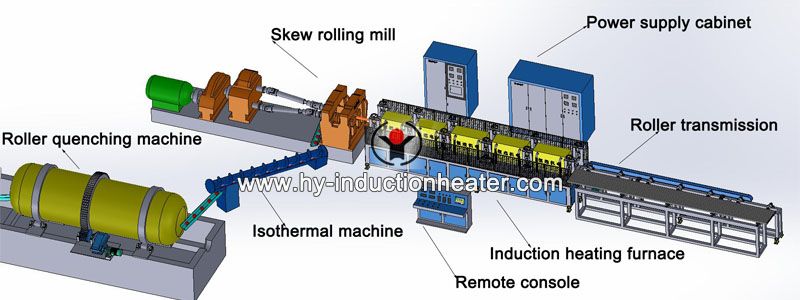

The automatic steel ball skew rolling production line adopts a fully automated production line operation without manual intervention, ensuring the stability of steel ball quality. The production process of this production line is environmentally friendly, energy-saving and efficient. The produced steel balls have precise dimensions, round geometric shapes, high hardness, and good mechanical properties, as well as high impact toughness and strong resistance to breakage.

Working principle of Skew rolling steel ball equipment

The working principle of spiral hole oblique piercing is shown in the figure. Two rolling rolls with spiral holes intersect with each other, and the rolling rolls rotate in the same direction to drive the circular rolling piece to rotate and move forward. Under the action of the spiral hole, the rolling piece forms a rotating part blank. The deformation of skew rolling is mainly due to diameter compression and axial extension.

The advantages of the Forever Grinding ball hot rolling heating furnace are mainly reflected in the following aspects:

1. Efficient production: The Forever oblique rolling steel ball production line adopts advanced induction heating technology, which can heat round steel to the required temperature in a short time and perform precise temperature control to ensure the stability and high quality of steel ball production.

2. High degree of automation: The furnace has a fully automatic hot-rolled steel ball production line, and the steel balls produced by rolling have standard size and good roundness.

3. Good product quality: The steel balls produced by the Forever oblique rolling steel ball production line have precise dimensions, round geometric shapes, high hardness, and good mechanical properties. They have high impact toughness and strong resistance to breakage. For example, the steel balls produced by the wear-resistant steel ball automatic rolling mill production line of Anyang Forging have these characteristics.

4. Energy conservation and environmental protection: The furnace is designed with full consideration of resource utilization efficiency. By optimizing energy use, the risk of environmental pollution is significantly reduced, which is in line with the national policy guidance for green transformation of the manufacturing industry.

5. Intelligent management: By introducing an AI monitoring system, real-time analysis of data during the transportation process can be conducted to predict faults and provide maintenance recommendations, reducing downtime for users and improving production continuity, thereby bringing significant economic benefits.

6. Customized production: Forever Electromechanical can customize production equipment according to customers’ actual needs to meet the requirements of different users.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 04-09-2025