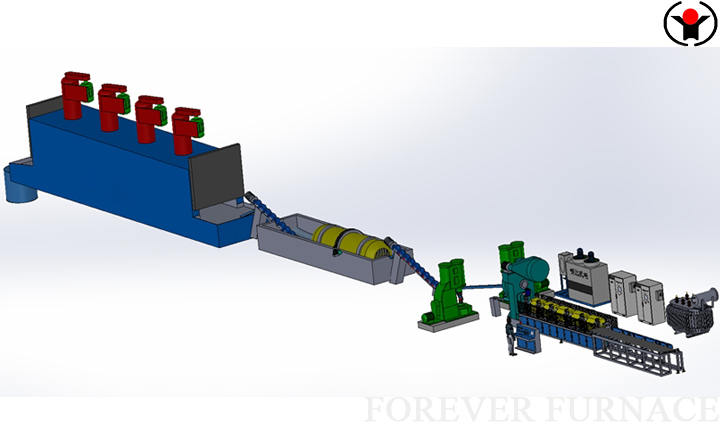

The steel ball hot rolling production line developed and manufactured by Hebei FOREVER electromechanical Co., Ltd., with power ranging from 500kW to 5500KW, can be used for rolling steel balls with diameter of 25-125. Siemens PLC control system can store, query and print process parameters of various specifications.

The design of steel ball skew rolling production line has the following characteristics:

1. The steel ball hot rolling equipment adopts network induction heating power control, with low power consumption and high production efficiency;

2. Simple adjustment and easy operation;

3. Firm locking and high stability;

4. Guide plate replacement is simple, fast and efficient. It provides a guarantee for the stable, efficient and high-quality operation of induction heating equipment for steel ball hot rolling.

5. Automatic control of heat treatment quenching temperature to ensure quenching quality;

6. Roll automatic fast back function ensures that the roll will not be damaged during rolling;

7. Automatic feeding function to improve the yield.

8. The steel balls produced by the Grinding steel ball production line have exquisite appearance, high hardness and high damage rate.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 06-24-2024