Composition: seamless steel pipe induction annealing equipment mainly consists of induction heater, intermediate frequency power supply, feeding rack, PLC control system, spray quenching system, cooling tower, etc. Other devices can also be configured according to user needs.

Working principle: High frequency current is passed through a heating coil to generate magnetic field lines, which are concentrated on the heated object. Electromagnetic induction is used to generate eddy currents, which heat the heated object.

Performance advantages: good straightness, less oxidation and decarburization, uniform heating temperature, high temperature control accuracy, small temperature difference, no pollution, high degree of mechanization and automation.

seamless steel pipe heat treatment furnace

Configuration and workflow: Storage rack → Material conveying rack → Power cabinet → Operating table → Induction heating → Spray quenching → Output rack → Receiving rack.

Features: Designed according to the user’s on-site situation, ensuring high heating efficiency, uniform temperature, convenient use, and long service life; Design a well sealed system that does not generate high temperatures, noise, or dust during operation; The transmission system is driven by an infinitely adjustable frequency converter, which has high controllability; Compared to other heat treatment equipment, the output is higher and energy-saving by about 20%; Reasonable material selection and structural design of parts make production more reliable.

Configuration components: Variable frequency air-cooled or water-cooled induction heating power supply range (IGBT200-1500KW), induction heater, quenching sensor, closed cooling system, copper bar connecting wire, input/output system, central console, equipped with American Raytheon infrared thermometer, etc.

Features: Adopting intelligent PLC control program, the intermediate frequency power supply has a remote SCR intelligent series resonance design, full open rectification, high power factor, small harmonic component, fast heating speed, no overburning or cracking after steel pipe treatment, strong toughness, tensile strength and straightness can meet customer needs.

The seamless pipe hardening and tempering furnace adopts the principle of electromagnetic induction heating and is a non-standard medium frequency induction heating equipment. It belongs to non-contact steel pipe induction heating and is widely used in the heating of steel pipes, thermal spraying heating, anti-corrosion heating, pipe shrinking, pipe expansion and other fields.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

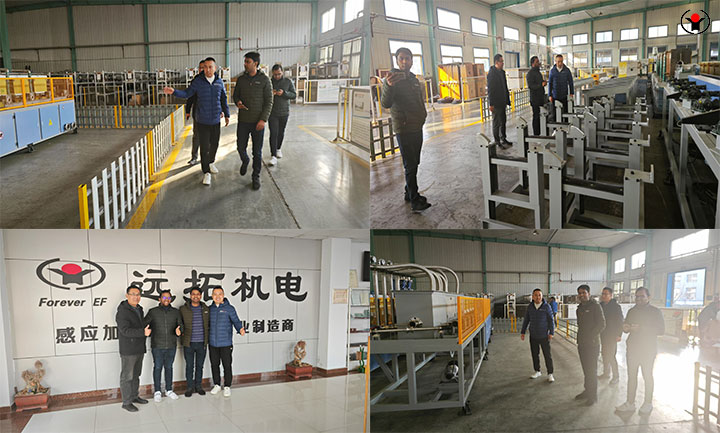

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 03-11-2025