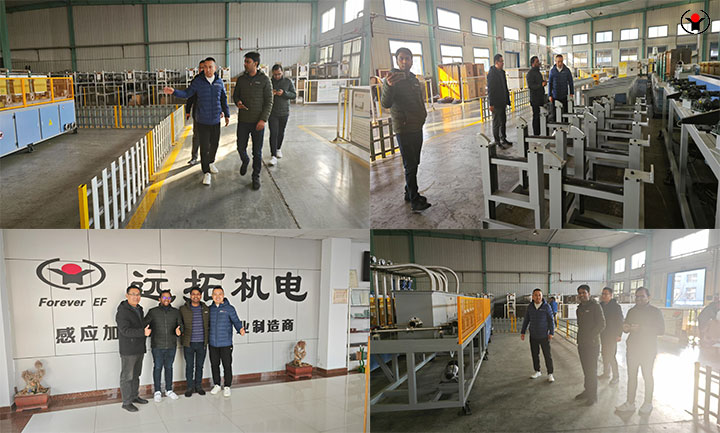

Forever Electromechanical is a domestic manufacturer of induction heating equipment. The seamless steel pipe annealing equipment produced is controlled by an air-cooled energy-saving IGBT induction heating power supply. It can be used by connecting the power supply, with low power consumption and high production efficiency. It is recommended to purchase high-quality seamless steel pipe heat treatment equipment from Hebei Forever Electromechanical Equipment Manufacturing Co., Ltd.

Configuration and workflow of Forever Electromechanical seamless steel pipe quenching and tempering equipment:

Storage rack; Material rack; Power supply cabinet; Console; Induction heating; Spray quenching output material rack; Material receiving rack

The pipe heating equipment produced by Yuantuo Electromechanical can ensure the stable performance of heat-treated steel pipes, reduce production costs, and improve production efficiency.

The Seamless steel pipe annealing furnace includes two processes: quenching and tempering. Among them, quenching adopts the following method: first, the seamless steel pipe is induction heated to 0-50 ℃ below the quenching temperature, then placed in the quenching furnace to ensure its temperature is at the quenching temperature, and kept warm, and then cooled;

The tempering method is as follows: the seamless steel pipe is induction heated to 0-50 ℃ below the tempering temperature, then placed in the tempering furnace to ensure its temperature is at the tempering temperature and kept warm, and then air cooled to room temperature.

Characteristics of Forever Electromechanical Seamless steel pipe hardening tempering furnace :

1. Forever Electromechanical seamless steel pipe quenching and tempering equipment is designed according to the user’s on-site situation, ensuring high heating efficiency, uniform heating of workpieces, and convenient use with a long service life.

2. The intermediate frequency quenching and tempering equipment has a well-designed sealing system, reliable sealing effect, and does not produce high temperature, noise, or dust during equipment operation.

3. The transmission system used in the seamless steel pipe heat treatment and tempering equipment is driven by an infinitely adjustable frequency converter, which can adjust the length of the workpiece, heating temperature, heating speed, etc. The equipment runs stably and has high controllability.

4. Compared to other heat treatment equipment, the production output of seamless steel pipe quenching and tempering equipment with the same power size is higher, and it also saves about 20% energy.

5. The selection and structural design of parts for the seamless steel pipe quenching and tempering production line are reasonable, and the coordination of various equipment components is reasonable, resulting in more reliable production.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 03-25-2025