Induction heating technology was first applied in industries such as military, automotive, and machinery in China, and later gradually expanded to the metallurgical industry. The use of medium frequency induction heating technology for heat treatment of steel pipes not only reduces environmental pollution and increases production efficiency, but also achieves a cost comparable to gas heating; If used during low peak periods of electricity consumption, the cost is lower. At the same time, if the process parameters are selected reasonably and the process control is well done, even the straightening process can be omitted.

Seamless pipe heat treatment machine: The quenching and tempering assembly line is equipped with a feeding rack at one end, and the workpiece is manually placed in the feeding rack. The oil cylinder pushes the workpiece to slowly feed on the roller. According to the workpiece specifications and heating speed, the hydraulic device is equipped with a hydraulic speed control valve to control the feeding speed of the oil cylinder. After setting the efficiency, the oil cylinder will automatically push the material once every certain period of time. After the material enters the electric furnace sensor, the electric furnace will start heating.

seamless pipe hardening and tempering furnace

In the production process of seamless steel pipes, in order to obtain the required performance, heat treatment is required. The heat treatment of seamless steel pipes generally includes annealing, normalizing, quenching, and tempering. Quenching is a heat treatment process in which seamless steel pipes are heated to a given temperature above the phase transition temperature, held for a certain period of time, and then rapidly cooled. The purpose of quenching is to obtain martensite, so as to obtain the required mechanical properties after tempering at an appropriate temperature. Tempering is a heat treatment process in which seamless steel pipes are heated to a temperature below the transition temperature from austenite to pearlite, and then cooled to room temperature after appropriate insulation. The purpose of tempering is to obtain the required microstructure and properties for seamless steel pipes. The process of combining quenching and high-temperature tempering to obtain a certain strength and toughness is called quenching and tempering heat treatment.

Our company adopts online continuous heating and is equipped with infrared temperature measurement devices to meet the heating process requirements based on the special heating method of steel pipes. The automatic detection and control of heating temperature can be achieved, and temperature adjustment can be achieved by adjusting the power. Round steel (pipe) quenching and tempering is driven by a speed regulating motor. After changing the specifications of the steel pipe, the operating speed and power can be adjusted freely, and all operations are implemented by the central control system. Workers only need to start and stop the buttons in the operating system to achieve fully automatic control of all actions (including power regulation, temperature display, mechanical motion, etc.).

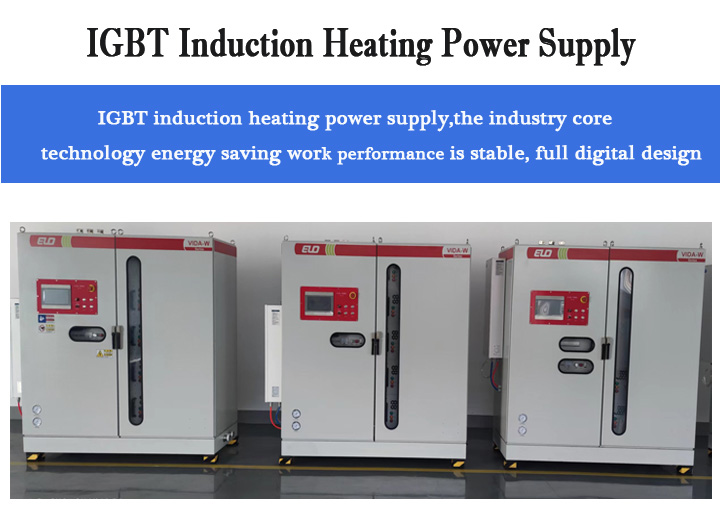

This is our intermediate frequency induction heating power supply

Post time: 09-14-2024