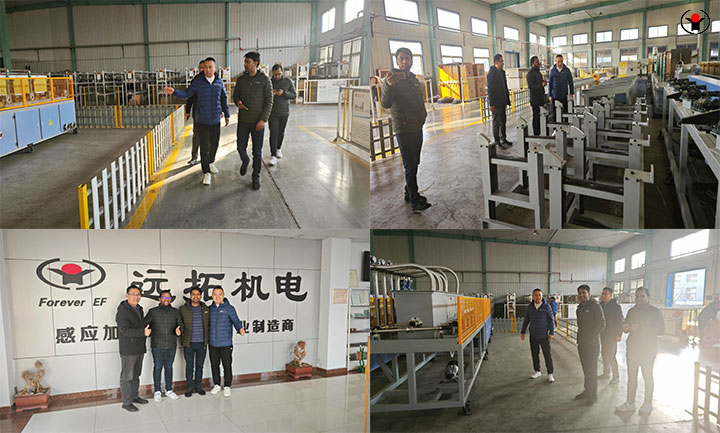

Hebei Forever Electromechanical is a large manufacturer of steel plate induction hardening and tempering production line in northern China. Forever Electromechanical’s plate heat treatment and tempering equipment has excellent quality and strict quality control, with fast heating speed and high efficiency. The components of the plate heat treatment and tempering furnace are all made of internationally renowned brands with long service life. Forever Electromechanical Equipment is sold to multiple countries and regions both domestically and internationally. Welcome to inquire about the Forever Electromechanical Induction Heating Equipment project. We look forward to hearing from you.

The centralized frequency power supply, mechanical system, heating system, and control system of the plate heat treatment and tempering equipment are integrated technologies. Based on more than 10 years of experience in the design, production, sales, and service of induction heating equipment industry, combined with the development of modern industrial technology and extensive absorption of advanced foreign technology concepts, Forever Electromechanical has independently developed and designed a new type of high-efficiency Steel plate induction heat treatment furnace. The sheet metal heat treatment and tempering furnace has the world’s advanced induction heating technology, which has many advantages that traditional heat treatment equipment cannot compare with: high heating efficiency, low production cost, easy maintenance and adjustment, excellent quality of heat treatment products, and can be widely used in heat treatment and tempering operations.

Performance characteristics of Forever Electromechanical steel plate heat treatment machine :

1. The efficiency of structural upgrading is higher, and the rectification power factor of the plate quenching and tempering equipment is greater than or equal to 0.92, which has a higher production efficiency. At the same time, the equipment has a small size and low noise: 2. With a large production volume, the plate heat treatment and tempering furnace sets the equipment power size according to the user’s production output requirements, achieving full power output and improving factory production efficiency; 3. The local heating furnace for sheet metal adopts fully digital intelligent production, equipped with PLC and touch screen to achieve operation and control of the entire equipment, with strong automation production capacity. 4. The quenching and tempering equipment for sheet metal adopts temperature closed-loop control, with accurate temperature measurement to ensure uniform heating temperature of the workpiece and excellent heat treatment quality; 5. It has complete protection against overcurrent, overvoltage, undervoltage, phase loss, water pressure, water temperature, etc., ensuring that any faults do not damage equipment components and ensuring production safety.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 03-07-2025