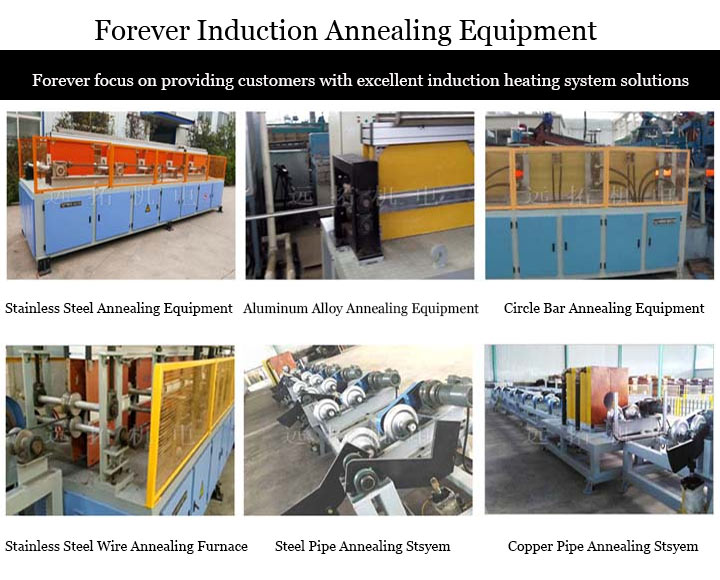

Forever specializes in manufacturing fully automated production lines for medium frequency annealing equipment for steel pipes, which are intelligently controlled by PLC and monitored by computers throughout the production process. The production process of the Steel pipe induction annealing equipment is efficient and energy-saving.

The company has a team of experienced experts in the induction heating industry who specialize in designing medium frequency annealing equipment for steel pipes and tailor it to your needs. Fully automated feeding, heating, and unmanned operation throughout the entire process, with a comprehensive power control model ensuring the temperature control accuracy of the steel pipe induction heating equipment.

The composition of the overall medium frequency annealing equipment for steel pipes consists of several parts, including medium frequency induction power supply, PLC control panel, closed cooling tower, input/output system, induction heating system, etc.

Characteristics of medium frequency Pipeline induction annealing equipment:

1. The overall medium frequency annealing equipment for steel pipes adopts non-contact heating with high heating temperature.

2. Temperature closed-loop control, using a dual color American Raytheon infrared thermometer to control temperature, with real-time display of the current temperature function

3. ; The copper tube of the sensor is designed with uniform turns and has been designed by engineers who have worked for many years. The temperature is easy to control, and the insulation performance of the sensor is good. The surrounding area is protected by a yellow 8mm to 10mm thick insulation board, which has a long service life.

4. PLC human-machine interface, highly user-friendly operation instructions, fully digital and deeply adjustable parameters, providing corresponding language switching according to different countries and regions, with the function of one click restoration to the factory date.

5. The V-shaped roller adopts 304 non-magnetic stainless steel pattern type, which can ensure more stable performance of the workpiece during operation.

6. The processed workpiece has no over burning, no cracks, and does not require straightening, with a finished product rate of over 98%.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 04-27-2025