Hebei Forever Electromechanical Equipment Manufacturing Co., Ltd. is an experienced, developed, and professional supplier of long bar induction hardening and tempering machine in China. Please provide us with the relevant parameters of the workpiece, process requirements, production output, etc. when consulting. Forever Electromechanical will customize a rational technical solution for the quenching and tempering heat treatment production line of long steel bars for you!

Forever Electromechanical’s large steel bar heating equipment generally consists of intermediate frequency power supply, electric heating capacitor, induction furnace body, pneumatic or electric pushing material, and other components. When configuring fully automatic production, it also includes automatic feeding sorting device, flat vibration feeding or chain feeding device, pressure roller feeding device, and temperature automatic control system. The long bar material quenching and tempering production line adopts Siemens PLC and operation screen to control the entire process of equipment production, with functions such as parameter display, recording, query, and alarm; The temperature control of the Steel bar induction hardening and tempering production line adopts advanced mathematical model calculation and power factor self correction control methods, which can achieve good control of batch temperature stability.

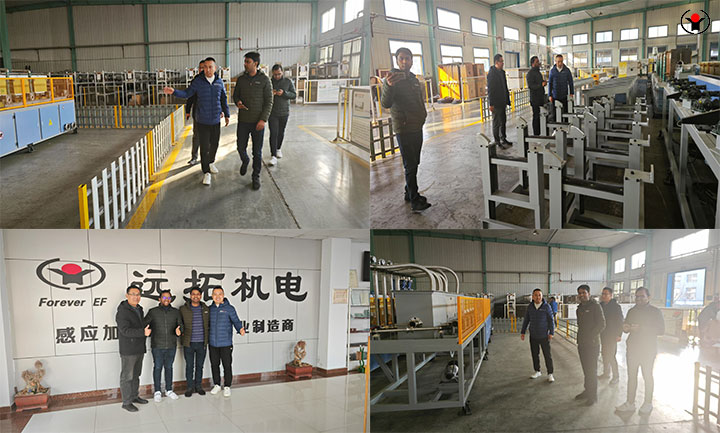

Characteristics of Forever Long bar induction heat treatment machine

Efficient and energy-saving: Adopting advanced IGBT frequency conversion control technology, it can accurately control heating power and frequency according to different process requirements, achieve efficient and fast heating, fully utilize the superior performance of the product, and reduce energy consumption.

Accurate temperature control: Equipped with American Raytheon infrared thermometer and forming a closed-loop control system with German Siemens S7, it can achieve precise measurement and control of quenching and tempering temperature, with a small temperature fluctuation range, ensuring the stability of product quality.

High degree of automation: It has functions such as fully automatic control and computerized information management, which can achieve real-time monitoring and management of the entire production process, improve labor productivity and management level.

Easy to operate: Ordinary employees can operate the equipment with simple training, ensuring stable and reliable operation with low maintenance costs.

Wide applicability: It can be used for quenching and tempering of various specifications of steel bars, supporting steel bars with diameters ranging from 10mm to 200mm and lengths of 1-6 meters. It is widely used in industries such as automobiles, motorcycle parts, steel rails, aerospace, weapon manufacturing, and machinery manufacturing.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 03-04-2025