The sucker rod induction hardening and tempering furnace uses electromagnetic induction to reach the quenching temperature in a short period of time. Compared with the traditional one by one heating method, it shortens the heating time, improves the uniformity of heating, ensures the efficient operation of the entire quenching production line, and avoids the surface hardness inconsistency and internal stress problems caused by traditional heating methods.

Scope of application: Suitable for quenching treatment of sucker rods with a diameter of 16-32mm.

Technical parameters: Heating steel grade Material: Oilfield sucker rod. The size of the sucker rod that requires surface quenching is (Ø 16, Ø 19, Ø 22, Ø 25, Ø 32) mm × (7520-9100) mm.

Quenching heating temperature: 850 ℃ (specific heating temperature will be adjusted according to hardness requirements).

Equipment power: 200KW.

Technical features of sucker rod induction heat treatment equipment :

Automatic Avoidance Function: The oil rod rotates through the roller, which has the function of automatically avoiding the head of the oil rod; To reduce quenching deformation, pressure roller devices are installed on both sides of the sensor, and both have the function of automatically avoiding the end of the oil rod.

Numerical Control System Control: The conveying device is controlled by a self-developed numerical control system to ensure the speed of the pumping rod during the conveying process.

PLC device control: Both heating and conveying are controlled by PLC devices, which can automatically avoid heating the threaded part and automatically control the transition section of the head heating of the pumping rod. The rotation speed, conveying speed, and heating power can be automatically adjusted to make quenching more uniform.

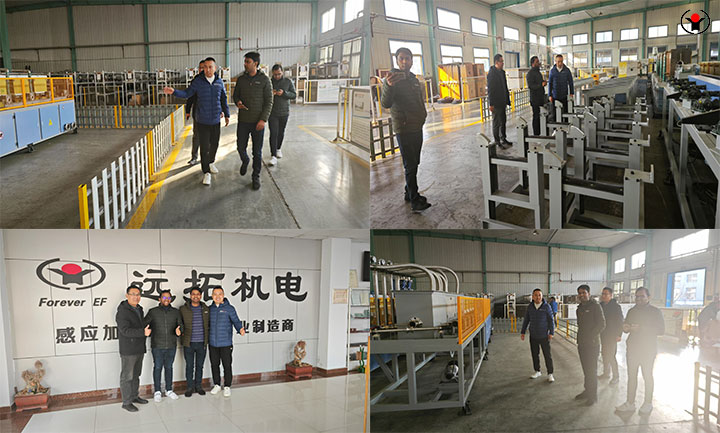

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 03-19-2025