Induction heating equipment is an efficient and precise industrial heating device composed of multiple core components, each of which plays an important role in the operation of the equipment. The following is an introduction to the main components and functions of the induction heating equipment provided by Yuantuo Electromechanical:

Power system

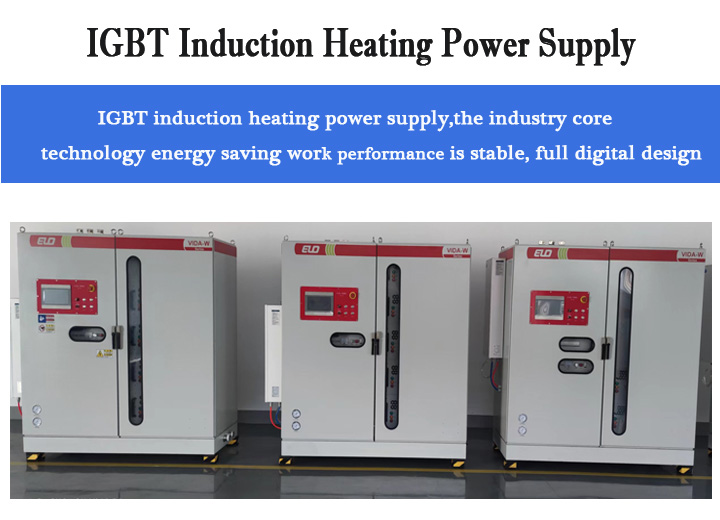

Variable frequency power supply: Variable frequency power supply is one of the core components of induction heating equipment, used to convert power frequency power supply (50Hz or 60Hz) into medium frequency, high frequency or ultra-high frequency current. The frequency converter provides different frequencies of current according to the material and process requirements of the workpiece, drives the induction coil to generate a magnetic field, and thus achieves heating of the workpiece.

Rectifiers: Rectifiers convert AC power to DC power and provide DC input for frequency converters. It is usually composed of diodes or thyristors to ensure the stability and efficiency of the power supply.

Induction coil 2

Coil design: Induction coils are key components that convert electrical energy into magnetic field energy. The design of a coil includes factors such as shape, number of turns, size, and quality, which directly affect the heating effect.

Common coil shapes include circular, rectangular, spiral, etc., and the specific choice depends on the shape and size of the workpiece.

Coil material: The wire is usually made of highly conductive copper or copper alloy material to reduce electrical energy loss and improve heating efficiency. In order to avoid high-temperature damage, a high-temperature resistant insulation layer or cooling system is usually installed on the surface of the coil.

3. Cooling system

Water cooling system: Due to the large amount of heat generated during induction heating, a cooling system is essential. The water cooling system effectively removes excess heat by circulating cooling water in the induction coil and other key components, preventing equipment from overheating and maintaining stable operation.

Oil cooling system: In certain specific applications, such as high-power or long-term operating equipment, an oil cooling system may be used to further enhance the cooling effect by utilizing the efficient heat transfer performance of the cooling oil.

Control system

Temperature controller: Accurate temperature control is crucial for induction heating equipment. The temperature controller senses the temperature of the workpiece through feedback and adjusts the power output to maintain the set heating temperature, ensuring the stability and consistency of the heat treatment process.

PLC controller: PIC (Programmable Logic Controller) system is used to automate the operation of induction heating equipment, including starting, stopping, parameter adjustment, and fault detection. The PL controller can preset multiple heating programs to meet different process requirements, improve equipment flexibility and intelligence level. Heating workbench 5

Workpiece support device: The workbench is an area for placing and fixing workpieces, usually designed with adjustment functions to accommodate workpieces of different sizes and shapes. The workbench material needs to have good heat resistance and mechanical strength.

Mobile and positioning systems: In some high-precision applications, workbenches are equipped with automatic mobile and positioning systems that can adjust the position of workpieces according to process requirements, ensuring uniform and precise heating

Sex.

On the human-machine interface (HI)

Touch screen or button panel: The human-machine interface is the bridge between the operator and the device. Through the touch screen or button panel, the operator can easily set parameters, monitor the operating status of the device, and perform fault diagnosis and handling.

Remote monitoring and control: Modern induction heating equipment usually supports remote monitoring and control functions. Operators can view the equipment status in real time through the network and perform remote debugging and maintenance, improving operational convenience and safety.

Induction heating equipment consists of main components such as power system, induction coil, cooling system, control system, heating worktable, and human-machine interface. These components cooperate with each other to ensure efficient operation of the equipment. Understanding these key components and their functions helps to better operate and maintain the equipment, thereby achieving stable and reliable heating effects. If you have any further questions or need technical support for a specific component, please feel free to contact us at any time!

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Post time: 09-01-2024