The steel ball production line from steel bars directly affects the performance and production efficiency of the steel balls. Choosing appropriate heating equipment based on different production needs is crucial for improving production efficiency and ensuring product quality. Hebei Yuantuo Electromechanical combines industry experience to provide you with detailed selection comparison analysis, helping you make wise choices.

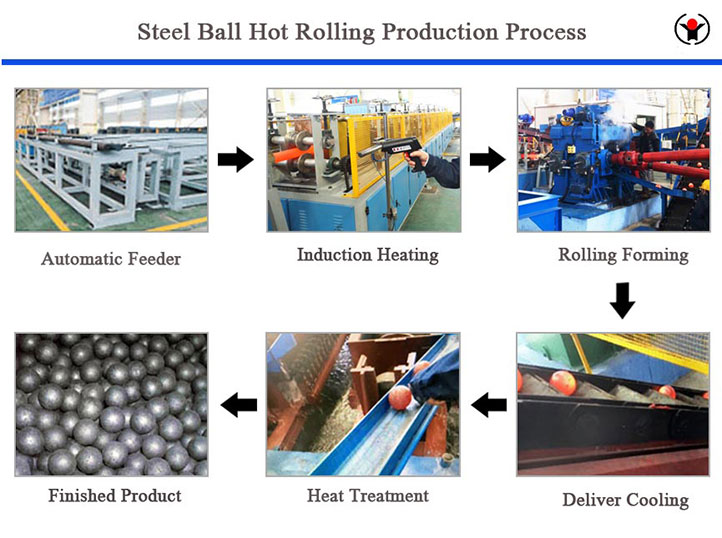

Grinding steel ball production equipment

1. Matching production scale with equipment power

-Small scale production: Suitable for selecting equipment with lower power, which can save investment and meet the needs of small-scale production.

-Large scale production: High power equipment can meet the needs of high efficiency and continuous production, suitable for long-term operation of production lines, and enhance overall production capacity.

steel ball rolling production line

Hebei Yuantuo Electromechanical suggests that if your production scale is small and the equipment with lower power can meet production needs and effectively control initial investment. For large-scale production lines, choosing high-power equipment can improve production efficiency and meet long-term production needs.

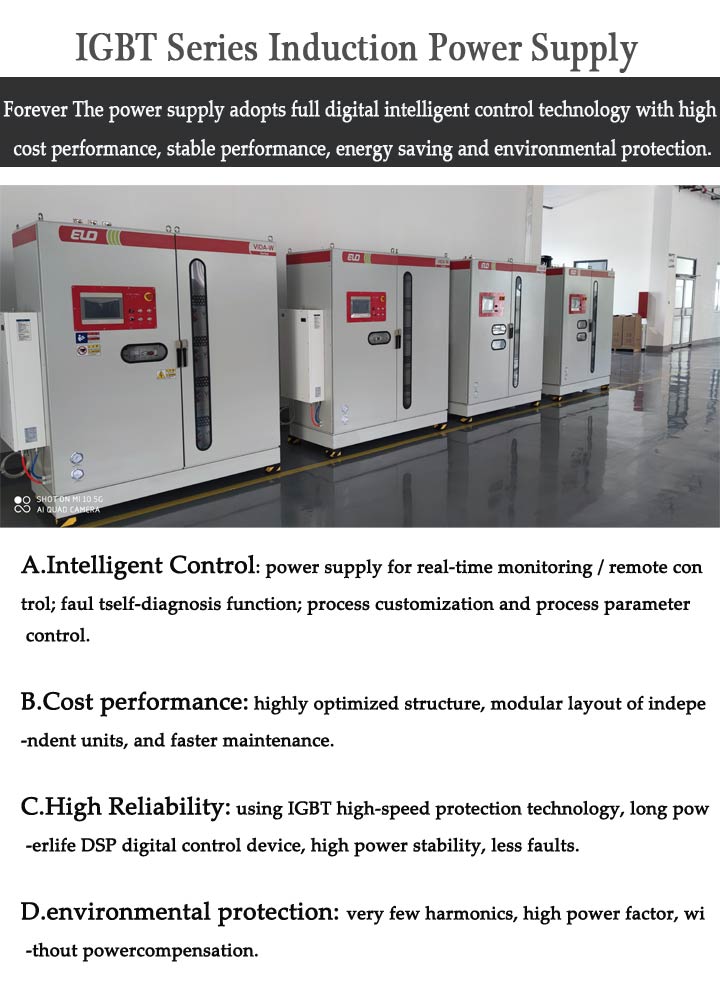

2. Heating technology and product quality

-Induction heating: Suitable for production processes with fast heating speed and high temperature control accuracy requirements, it can effectively improve the hardness uniformity of steel balls.

-Resistance heating: Suitable for processes with low heating accuracy requirements and short production cycles, and suitable for low-temperature production requirements.

Hebei Yuantuo Electromechanical suggests that for customers who have high requirements for heating accuracy and efficiency in steel ball production, induction heating equipment would be a more suitable choice; For small-scale production, resistance heating equipment can achieve a balance between accuracy and production speed.

3. The relationship between automation and manual intervention

With the improvement of the level of intelligence in manufacturing, the degree of automation of equipment has also become an important reference for enterprise selection.

-Low automation equipment: suitable for scenarios with short production cycles and minimal manual intervention.

-High automation equipment: suitable for large-scale production, capable of real-time monitoring of production data, reducing manual intervention, and improving production efficiency.

Customer visit

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 03-01-2025