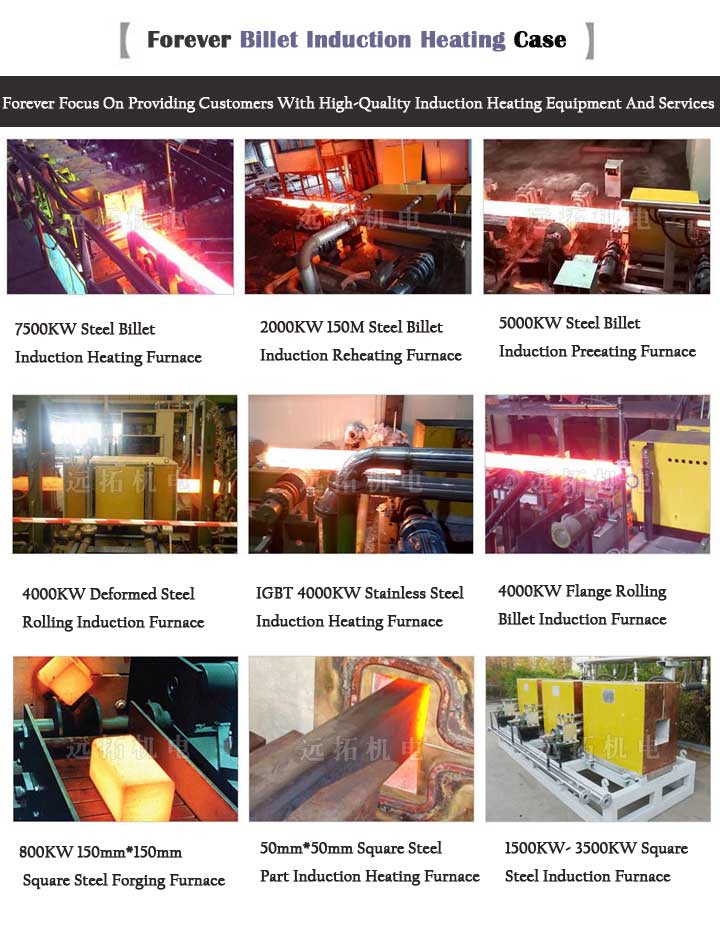

Forever specializes in manufacturing fully automated production lines for continuous casting billet heating furnaces, controlled by PLC intelligent control and monitored by computers throughout the production process of continuous casting steel billet heating electric furnaces, with high efficiency and energy saving. The company has a team of experienced experts in the induction heating industry, specializing in designing continuous casting steel billet heating electric furnaces and tailoring them for you. Fully automated feeding, heating, and unmanned operation throughout the entire process, with a comprehensive power control model to ensure accurate temperature control of the intermediate frequency continuous cast billet heating machine .

Process parameters of steel billet continuous casting and rolling heating furnace :

1. Continuous casting billet size: 6000 (length) x 150 (width) x 150 (thickness)

2. The online speed is relatively high at 15m/min, with a speed adjustment range of 9-15mm/min. The speed of each steel billet is constant.

3. Temperature distribution

(1) The distribution characteristics of temperature zones in the cross-section of continuous casting billets indicate that the internal temperature belongs to the high-temperature zone, with a temperature of 1100 ℃; The external area is a low-temperature zone with a temperature of 800 ℃, which is the part that needs to be raised by 300′C.

(2) The temperature distribution characteristics of the head and tail of continuous casting billets are usually about 50 ℃ lower than that of the tail

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 03-31-2025