Automatic steel ball production line manufacturer

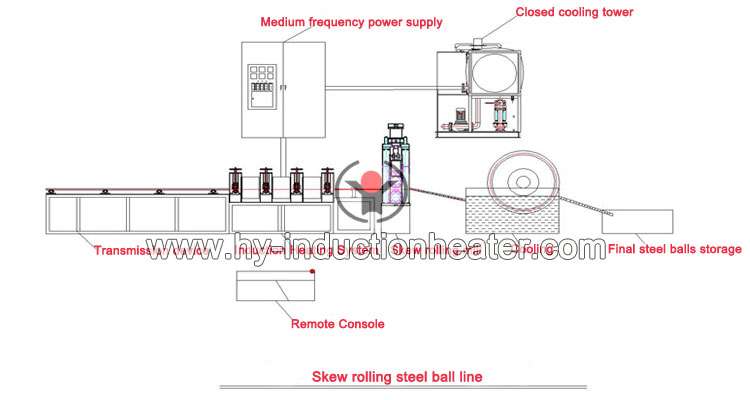

With the process breakthrough of hot rolled steel ball, it is gradually replacing the casting process, and become the development direction of steel ball production industry. Forever steel ball production line includes the feeder, heating furnace, skew rolling mill, quenching system, tempering system with advanced hot rolling process.

Description:

Using electric furnace instead of conventional coal combustion method, and the rotary cutting technology has replaced traditional air hammer, production efficiency is improved by 30 times or even higher. In addition, by controlling the leading-edge quenching equipment, high quality steel grinding balls with different hardness levels and mechanical properties could be produced, and they are characterized by high internal and external hardness, uniform hardness distribution, high impact toughness, better wear resistance as well as excellent shape maintenance without breaking apart.

Applications:

Production of steel balls, grinding steel balls for mining, cement plant, power station, chemical industry.

Steel ball or grinding steel balls available for diameter 16 mm-150 mm,we can give you solution as per your plant requirements.

【Advantages of steel ball production line】

1. Main body is with good rigidity.

2. Adjust is easy.

3. Locking is solid, high stability.

4. Easy to change guide plate.

5. Production is compete automation, high production efficiency, large output.

6. Low power consumption, no pollution.

If you want to build steel ball plants, please contact us,we have experience to give you the most power saving equipment configurations.

This article is from Forever-induction heating equipment manufacturer

Post time: 09-13-2016