Induction hardening furnace

Features:

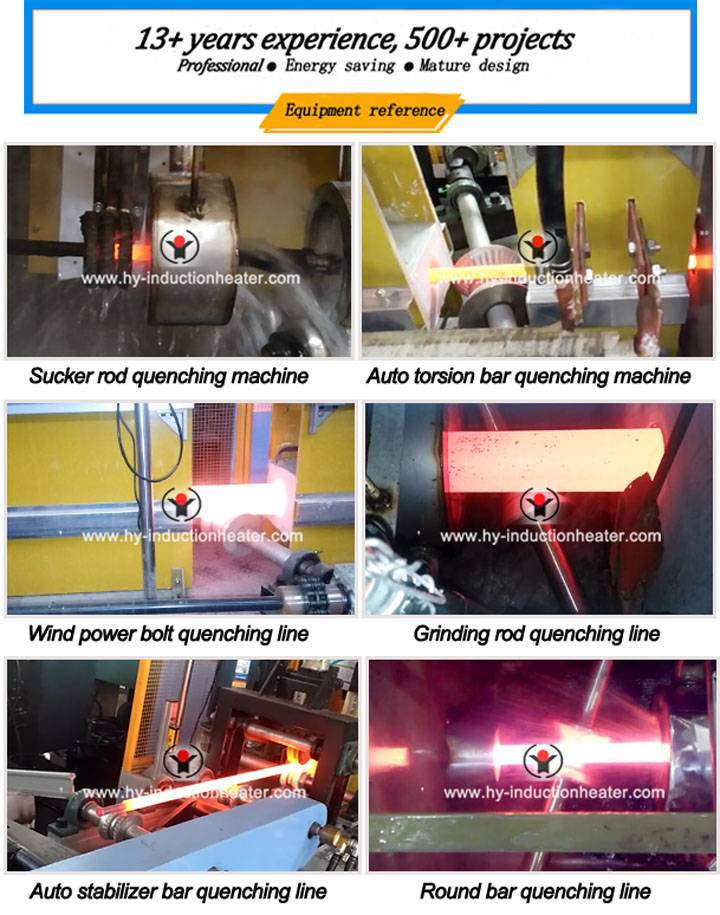

Application: Quenching & Hardening

Heating : Pipe, Tube, Bars,Rods

Diameter Allow: Φ20-300mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

● Product name:Induction hardening furnace

● Bar diameter available: ø20-150 mm

● Pipe diameter available: ø20-300 mm

● Length available: Not limited

● Heat treatment requirement: Reach to user’s request at yield strength, tensile strength, straightness.

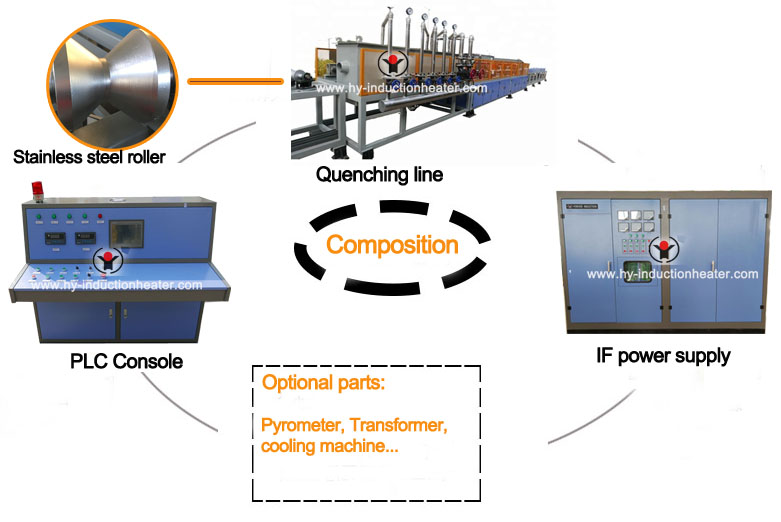

Forever induction hardening furnace is using Induction heating as heating method, which is fast, precise, clean, energy efficient, controllable and repeatable. With more than 1000 cases, our induction hardening has good features of fully automatic, uniform heating, simple operation and reliable performance.

Our induction hardening furnace is designed & produced as per user’s specific requirements with 100% temperature monitoring and recording.If you have other requirement about machine, we will try our best to meet your requirements.

Induction hardening furnace features

● Manual, semi-automatic and automatic systems

● Optional automatic loading and unloading

● Optional temperature continuous control and monitoring system

● Fast heating, low scale, high temperature uniformity

● Easy exchangeable inductors

● Power 100KW- 8000KW

● PLC controlled

Sprayer and inductor for induction hardening furnace

Sprayer: it is a circular spray device made of stainless steel, installed in the discharge end of the inductor, the work piece go through from the sprayer.The high-pressure cooling water from the spray hole wall will spray work piece for cooling There is water collecting tank below sprayer and the cooling water flows into the quenching circulating pool through water collecting tank.

Inductor manufacturing: Copper tube use T2 oxygen-free copper winding. The wall thickness of the inductor is more than or equal to 3.0mm. The material of inductor holding temperature has good features of high strength, high temperature resistance and longer service life. Using 5mm copper plate to cover inductor inlet and outlet,which can reduce the magnetic leakage and increase service life.The cabinet under the inductor is made of high strength aluminum alloy, which can reduce the magnetic leakage and the influence of heat on other devices.There is a water cooling carrier roller between every two inductors, equipped with one frequency conversion motor for each carrier roller.

Mechanical conveying part for induction hardening furnace

Adopting domestic brand Jiangsu Guomao GR67 series hardened motor reducer as the driving power; Using 40Cr steel as the feeding roller which is surface quenched; The rollers between inductors adopts 304 non-magnetic stainless steel and cooling by inputting water.

| Shaft diameter | Shaft length | Heating Temp. | Quenching depth | Production capacity |

| Ø16 | 4m | 900℃ | 1.1~2.3mm | 120 PCS/H |

| Ø25 | 4m | 900℃ | 1.1~2.3mm | 60 PCS/H |

| Steel bar diameter | Automatic Control | Power Design |

| Ø10-Ø28 mm | IPC Control | KGPS350KW Quenching+KGPS160KW Tempering |

| Ø42-Ø48 mm(Anchor Bolt) | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-60 mm | IPC Control | IGBT250KW Quenching+IGBT160KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-Ø110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

| Pipe diameter | Automatic control | Power design |

| Ø95,Ø114 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø73.2,Ø88.9,139.7 mm(Drill pipe) | IPC Control | KGPS500KW Quenching+KGPS100KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-Ø110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.