Hardening heat treatment furnace

Features:

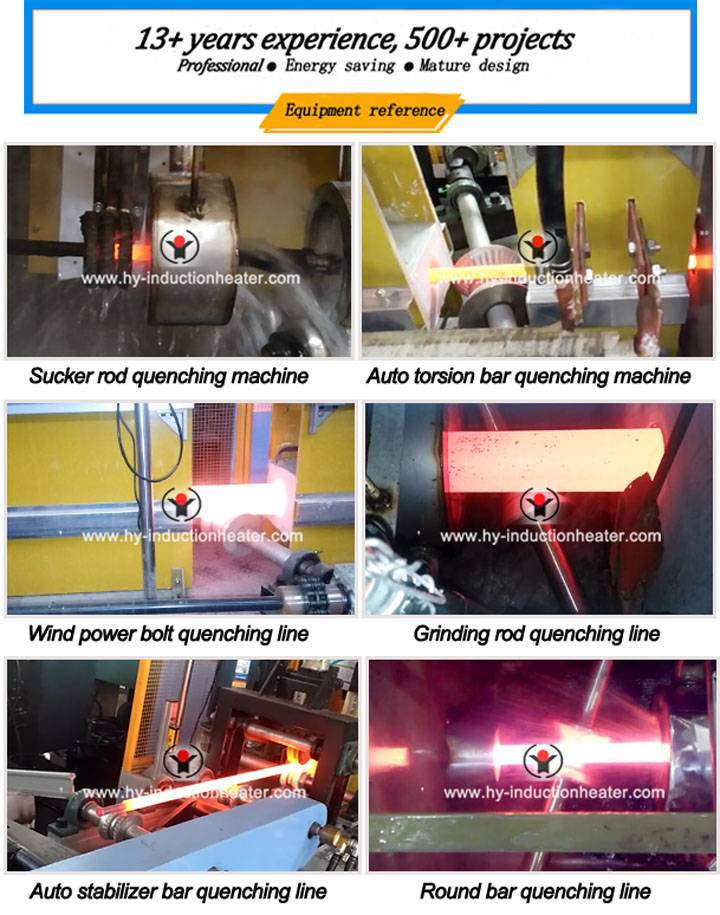

| Application | Bar,pipe,slab,billet,strip,wire,sucker rod,shaft,axle,gear hardening heat treatment |

| Power | 100KW-10000KW |

| Non standard |

Professional Customization |

Product Detail

Application Video

Product Tags

Product Name: Hardening heat treatment furnace

Typical Application:

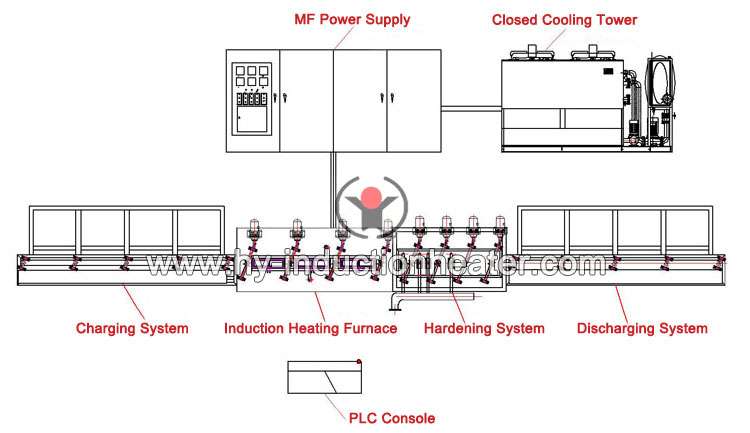

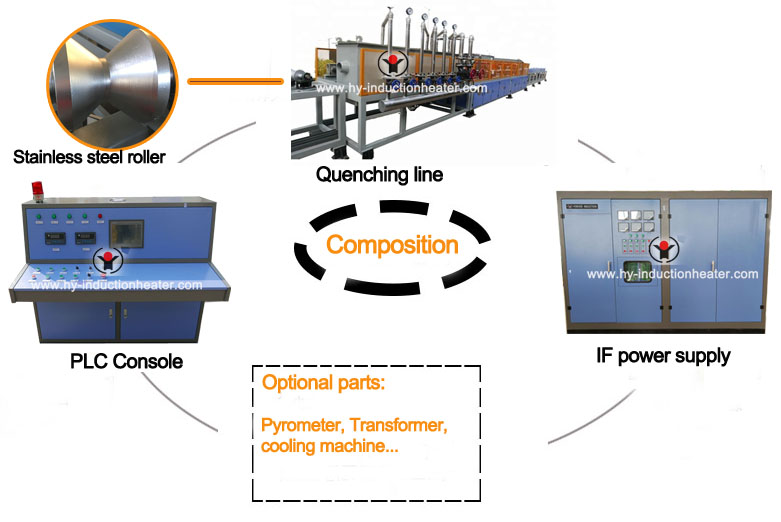

IF hardening heat treatment furnace includes IF power supply, transformer, hardening control cabinet, induction coil and hardening machine. IF hardening heat treatment furnace is used for whole material or partial hardening heat treatment, increasing the surface hardness and improve the durability of the work piece.Such as crankshaft, half shaft, fastener, large gear and other scanning quenching; wheel, driving wheel, guide wheel, and other integral quenching.

Hardening heat treatment furnace unique advantages

● Fast heating speed;

● Little deformation of work piece; uniform hardening depth and hardness;

● No change in the crystal structure, high degree of automation to ensure product quality;

● According to the actual temperature difference, IF hardening heat treatment furnace is also applicable to the tempering process.

In particular, our equipment can achieve certain depth or partial hardening compared with other methods.

The characteristics of hardening heat treatment furnace are:

1. The system is controlled by series resonant power supply with full digital & high power.

2.Fast heating rate, less oxidation and decarbonization.

3. The steel bar quenching furnace is carefully designed with high degree of automation. The automatic operation can be realized by selecting automatic feeding and automatic discharging and checking device and then matched with PLC control system.

4.Uniform heating, high temperature control accuracy, easy to achieve uniform heating, small core temperature difference. The temperature control system can realize precise control of temperature.

5. Adopt imported motor, drive by reducer of each shaft motor, control by independent frequency converter, control the running speed in sections.

6. The replacement of induction heater is easy to configure the induction furnace with different specifications according to the size of the workpiece.

7.The input and output conveyer are controlled by imported independent motors. The temperature of workpiece is controlled by the American retheter thermometer and displayed in real time.

Forever induction heat treatment furnace adopts closed cooling tower to control:

1. The main engine is using imported brand compressor from Japan and the United States, with built-in safety protection, low noise and power saving.

2. Electrical parts are the original products of Schneider, an international brand, to ensure that the machine works stably and has long life.

3.Import Italy original pump, large flow, high efficiency, durable.

4. Equipped with imported precision digital display temperature controller, it can accurately control the water temperature at ±1℃, and set the temperature range from 5℃-50℃.

5. All stainless steel thick water tank evaporator with built-in automatic water replenishing device.

More details, please check our website:【http://www.hy-inductionheater.com/】

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.