Billet induction reheating equipment

Features:

| Application | Steel billet heating before hot rolling |

| Power | 100KW-8000KW |

| Non standard | Professional customization |

| Temp.control | Infrared thermometer |

Product Detail

Application Video

Product Tags

Product Name: Billet induction reheating equipment

Typical application:

Billet induction heater is playing an important role of heating in the process of billet or rebar manufacturing.After the billet discharging from continuous casting machine,the billet induction heater will increase the heat of billet, then it will charge into rolling mills. Our billet induction heater is customized and non-standard, so please tell us the billet size, production capacity and the target temperature you need, then we will provide price and solutions for billet induction heater.

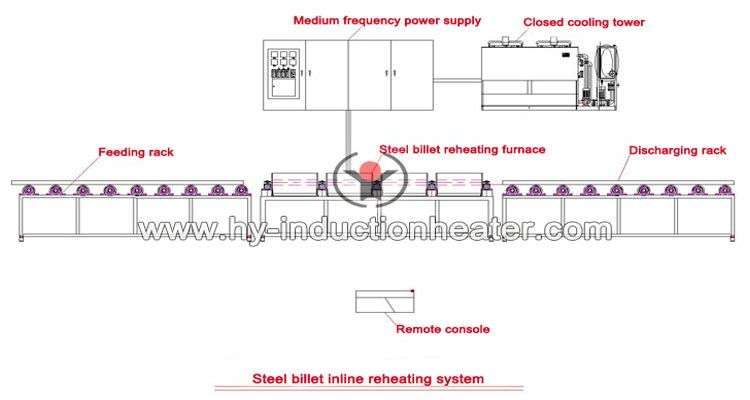

Billet induction heater layout

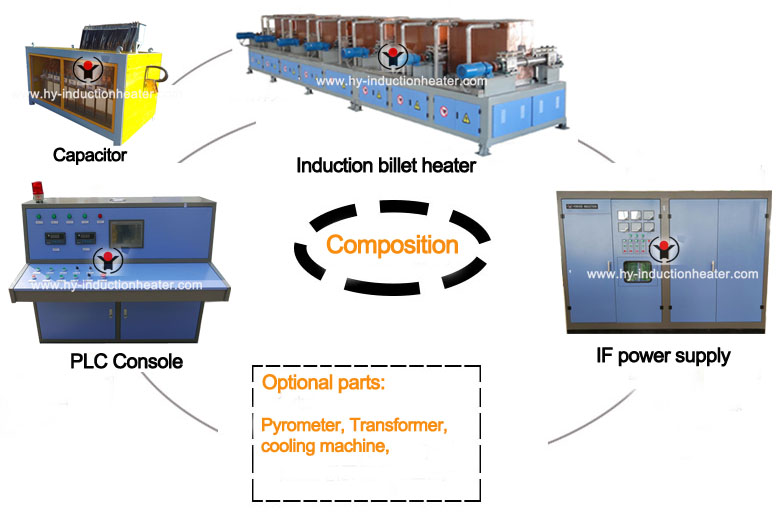

Introduction of billet induction heating furnace :

● MF power supply:reliable,power saving, low distortion, high efficiency, tin copper bar, water pipe is made of stainless steel.

● Billet induction heater:Both ends of the furnace body are sealed with the whole purple copper plate, and the base plate is made of high strength aluminum alloy.

● Connection cable:Electrical connection power supply cabinet to furnace.

● Capacitor:Enclosed, stainless steel water pipe.

● Remote control box: Siemens PLC can control billet temperature automatically.

● When the billet induction heater is no-load working,the system will reduce to the Min. power,when the billet is charging into induction heater, the device will increase to Max.power to work,which can reduce the power consumption greatly.

● Infra Red Pyrometer: Non contact type Infra Red Pyrometer can measure temperature of billet at the exit side.

Advantages of Forever billet induction heating equipment

● Heating fast and uniform.

● Power saving 10% or above:Less harmonics, high power factor, load output voltage is high, the load coil current is low,small power consumption.

● 100% successful starting.Reliable frequent starting is available.

● Easy installation & commission and simple operation.

● Safe and reliable.Perfect protections for long life performance and very safe for operators. Automatic protections for water temperature,water pressure,phase shortage,overcurrent and undervoltage.

High reliability:Adopt famous brand components which reduce fault rate and make sure the equipment can run reliably.

| Bar Diameter | Bar Length | Heating Temp. | Production capacity |

| Φ36-45mm | 1500mm | 1125°C ± 25 | 3T/H |

| Ø60mm | 6000mm | 1200℃ | 4.4T/H |

| Ø70mm | 6000mm | 1200℃ | 5.3T/H |

| Ø80mm | 6000mm | 1200℃ | 6T/H |

| Billet size | Billet length | Heating Temp. | Production capacity |

| 60*60mm2 | 3-4 m | 1000℃-1100℃ | 25T/H |

| 75*75mm2 | 3-6 m | Room Temp.-1100℃ | 25T/H |

| 100*100mm2 | 2 m | 750℃-1000℃ | 7T/H |

| 120*120mm2 | 750℃-1100℃ | 30T/H | |

| 120*120mm2 | 11.5-12.5m | 950℃-1150℃ | 90T/H |

| 125*125mm2 | 6 m | Room Temp.-1200℃ | 8T/H |

| 125*125mm2 | 2 m | 750℃-1000℃ | 7T/H |

| 130*130mm2 | 6 m | 950℃-1150℃ | 50T/H |

| 135*135mm2 | 6 m | 950℃-1150℃ | 100T/H |

| 150*150mm2 | 11.5-12.5m | 950℃-1150℃ | 70T/H |

Related product: Billet heating before hot rolling Steel billet reheating furnace Induction heating steel bar

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.